|

January 12, 2006

Tweed Deluxe Reverb? Never

heard of it! If Leo had wanted us to have one, he would have made it for us.

Who'd want it anyway?

........Well, I would! |

And I have for about 4 years now. It was 2002 and I had

just restored a 1957 Fender Harvard for an old high school buddy. Man, that amp

sure sounded good to my old ears. And I found myself drifting back to a chaotic

time in '65. I remembered how I would scoff at his little amp. Heck, he couldn't

even keep up with my old Silvertone twin 12! You know, the sixties was not as

focused on quality sound as "we" are today. There were no "boutique" amps.

IT WAS ALL ABOUT SOUND PRESSURE! CAN YOU FEEL IT! You old guys know what

I mean. I still remember the day our other guitar player showed up with a Super

Reverb. Now I couldn't be heard either! I took care of that soon enough though.

My first build back in '68 was a Sunn Sorado Bass amp. Sitting on top of twin CTS 15"

bass speakers with the biggest square magnets anyone had ever seen!

CAN YOU HEAR ME NOW!

Whoa. Got lost for a minute. Back to 2002. Yes, I kinda

liked that old Harvard. But it lacked a component that I considered essential.

THERE'S NO REVERB! Oh well, it is what it is. A long spring unit wouldn't even

fit anyway. And I wasn't about to suggest butchering that old piece of history.

And I didn't even know.....the seed was planted.

Then last November, I began itching to do one more build.

I hadn't done an amp since '76. Actually, I went acoustic and stayed that way

until 2003. I bought a Taylor 614CE and picked up an old Peavey Reno from eBay.

That sparked the old love for Strats. So, I'm checking out the 5E3 kits but it

just isn't exciting me to just assemble someone else's deal. Besides, that 5E3

is just too simple (from a technical standpoint). But in my quest to calm the

itch, I realized that the Tweed Deluxe cab was 20" wide. Hmmm, where's my tape

measure. I think a long spring may fit. And so, the seed sprouted. I barely remember Christmas. But I didn't care. I

was alive and 20 years old again and excited and running around gathering up

parts and asking questions. What a joy for an old fart to

rekindle a boyhood passion!

.....And so I was off to build my own Tweed Deluxe

Reverb.

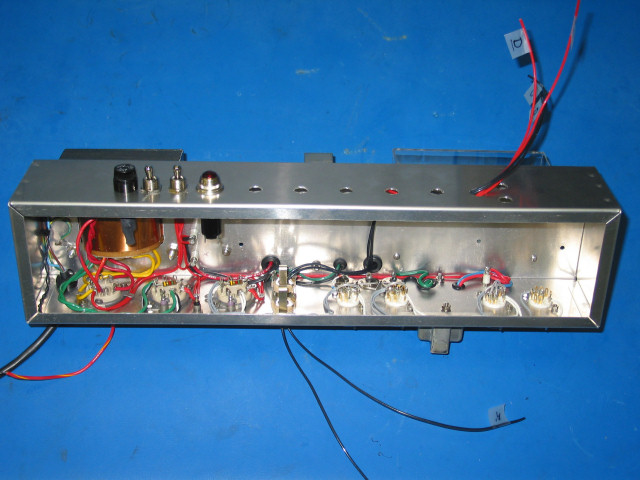

| In

the beginning... The project took life by

first taking the Deluxe Reverb AB763 schematic and stripping out the normal

channel and tremolo circuits. Then I added a bright switch and middle

control. After some fine tuning in Visio, I cranked out my final

working schematic.

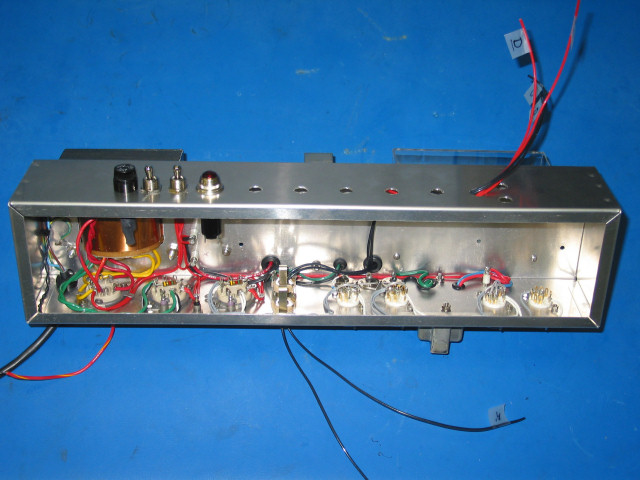

The aluminum chassis is a Hammond 1444-20, 17x4x3.

It's really thinner than I like. If I were to do this again, I'd use the

steel version of this chassis. It's not that much harder to work with.

However, it would have been a special order from Mouser, so I opted for

aluminum.

The PT cutout was done with a jig saw and some hand

filing. A router guide template would prove useful if doing several of

these, but I had a nice hole cut faster than I could have built the

template. All other holes were done in a drill press using HSS bits or a

step bit. The octal socket holes were punched with a 1 1/8" chassis punch.

The control panel layout was done using Visio. The

Tweed Deluxe cabinet has a 2" x 12 1/8" cutout, so I had to do some careful

layout work to get it all to fit correctly. Layout from left to right is

fuse, power, standby, indicator, reverb, master, bass, treble, volume,

bright, inputs. That's BUSY!

I had one design layout flaw that I caught while

wiring the filament string. I had placed the reverb in/out/footswitch jacks

below the reverb transformer for a nice looking and easy wiring job. But my

filament string was gonna be tucked away under the bottom lip of the chassis

and would pass very close to these jacks. So, to minimize hum, I relocated

the jacks and put a small cover plate over the original holes.

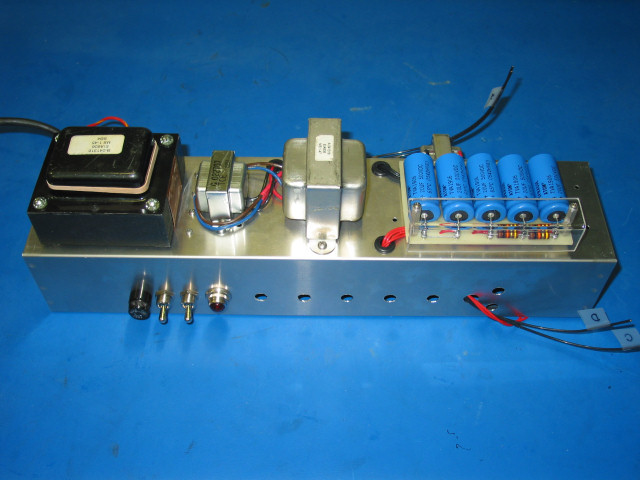

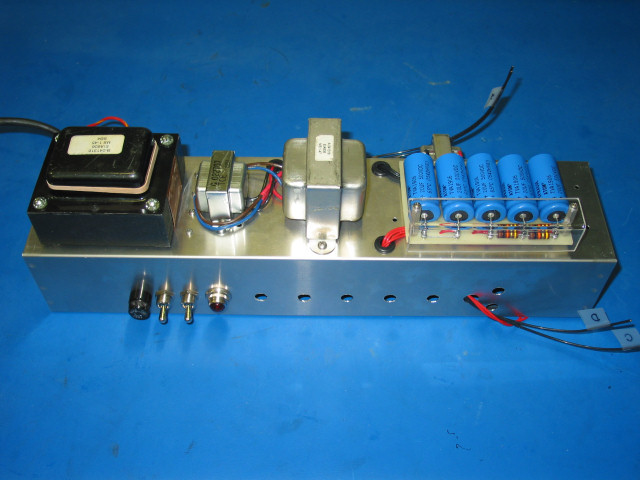

All caps came from Mouser. Materials to build the

turret board came from Hoffman. The safety shield for the caps was cut from

a sheet of 1/8" acrylic that was sandwiched between two wood blocks in a

vise. A heat gun was used to make the bend. Hopefully this will keep

careless fingers off the business end of those caps!

The transformer set is from a '65 DRRI and was

provided by MikeyMann. All wiring (except power cord and transformer leads)

is either 18 or 22 gauge teflon insulated 19 strand silver plated copper. I

had some on hand and bought the rest on eBay. (There really isn't anything

that can't be had from eBay!)

I already had all the miscellaneous stuff, tube

sockets, switches, indicator, fuse holder, standoff turrets, etc., from my

last build in 1976. Those gold plated sockets looked brand new. Some of the

other stuff got a good cleaning.

The next phase of this project is going to get

crowded, so this is a good time for some preliminary checks.

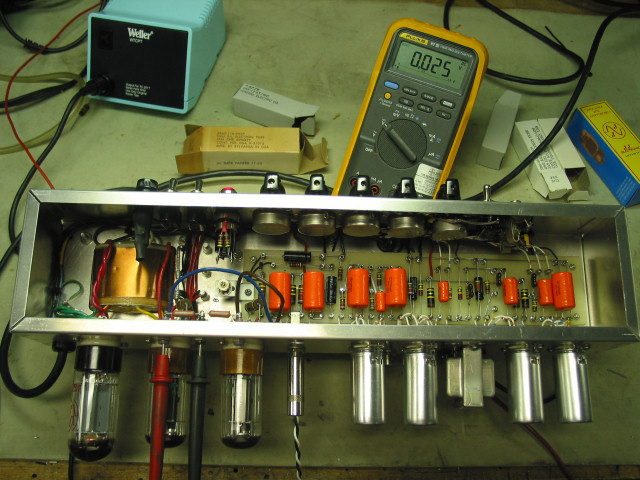

All external components have been installed but not

necessarily connected. Note that the HV center tap (red/yellow) and

bias tap (red/blue) are not connected at this time. At this point I did a

first power on check to verify PT operation and rectifier and filament

string wiring. All was well so I put all tubes in for a quick check for

lights. And finally, a voltage check between rectifier cathode and HV center

tap showed the expected unfiltered 120 hz. DC voltage. All checks

at this point passed so it's time to move on. |

|

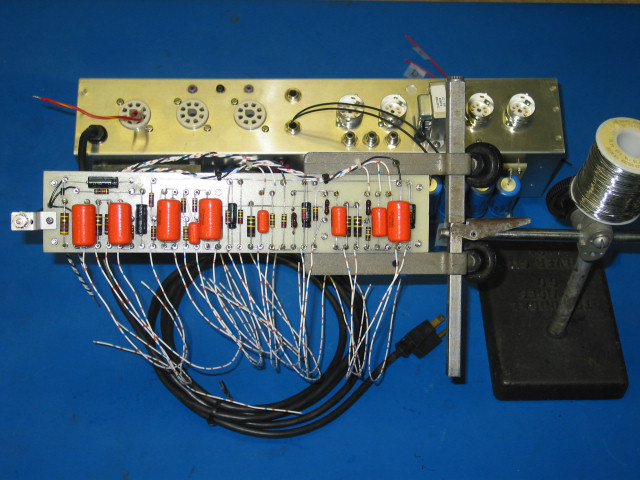

| The

tough stuff... Building the main board was

actually several challenges rolled into one. Divide and conquer. The board

needed to be about 2" wide to provide adequate wiring space inside the 4"

wide chassis. I spent several hours working with Visio to generate my layout

template. Then several more hours were spent going over and over, refining

and verifying that everything was correct. It's the old carpenter's rule,

measure twice, cut once. I didn't want to find out later that I needed one

more turret lug, or a jumper here, etc.

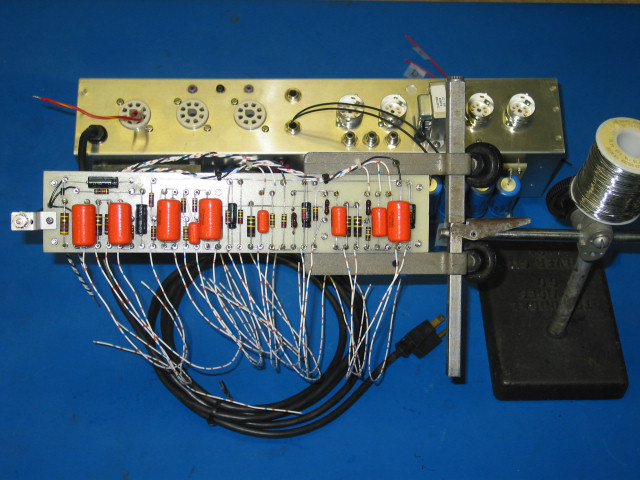

The final template measured 2.2"x10.8". Now the fun

part. The G10 board was cut to size and the full size template was printed

and attached to the board with double sided carpet tape. All holes were

carefully center punched and then drilled at the drill press. (This method

works fine for a one of a kind board) Then I used Hoffman's little flaring

tool set in the drill press to install the turrets.

Back to the soldering station to install jumpers,

wires and load the components. BTW, all resistors are carbon comp, 5%

tolerance, high reliability (yellow band = 25ppm, whatever that means!) mil

spec.

Here's the

board layout if you're curious. |

The board is fully loaded and ready to be installed.

Actually, this was to be the most challenging part of the entire project. I really

could have used a swivel jointed curved needle nose pliers with a

retractable cutter on the tip. (and one more quart of nerves!) By the time I

finished the tube side wiring, I was exhausted. The control panel would have

to wait. And there ain't gonna be no rematch, so

don't ask. |

|

Ground is ground. Right??? Now that's a science all

by itself! Not just with amp building, but with any complicated electronic

system. I work for FAA at an enroute radar station and believe me when I say

that a lot of R&D goes into a grounding and bonding system at such a

facility.

So I read up on amp grounding schemes. Aiken has some

excellent reading. And I pondered what to do....Star, multi-point star,

buss. They all have good points and grounding does not need to be taken

lightly, especially with an aluminum chassis. My ground system was the very

last thing I wired. I was hoping to come upon some magic solution.

But in the end, I went with my tried and true method

from 30 years ago. Single Point Ground is what I called it back then. I

guess some would call it a Star today, but hey, it could even be a 2" long

buss! |

|

|

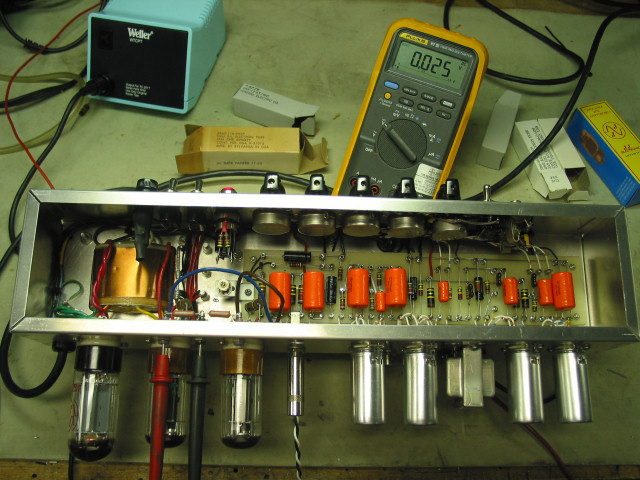

Something's burning... The chassis is 90%

complete at this point. I say 90% because you can never quite be sure that

some gremlin is not gonna rise up and piss in your coffee during the first

burn. I got lucky. The components held up and I only had one minor

wiring error. The coax cables that feed the grids for V1 run underneath the

main board. Yep, they got reversed. An easy fix that I caught just prior to

first burn. I dummy loaded the output and set the bias for 25 ma idle

current. All plate, screen, grid, and cathode voltages were checked and

found to be acceptable. I just let it cook that way for the remainder of the

day. I think it's always good to just let the juices flow at idle for a

while before applying an input signal. I made a point to stop, look, listen,

and smell every few minutes during the first hour. By the end of the day

confidence was high.

BTW, take a close look at that

old brown tube box just north of the chassis. Catch the packing date on that

dude? That's the same year I got started in all this stuff! |

First burn is always a rush. It's

usually either Miller Time or a very humbling experience. |

| It

feels like the first time... Well, it's

Friday morning, I'm home alone, what shall I do?

I think I'll try to make some noise. I connected into

one of the TRRI speakers, strung out the reverb cables and turned it on. It

made some noise all right. SQUEALED LIKE A STUCK PIG! Power off immediately

and fire up the soldering iron. My bet is the OT plate connections are

reversed. Hey, it's a 50/50 thing and I got it wrong the first time.

The Strat is plugged in and I'm having fun. Something

is not quite right though. Sounds like the gain is turned way way up even at a

minimal setting. This one took a couple hours to find, mainly because I had

to strongly suspect a wiring error or bad component. I danced all around the

problem for some time before realizing that the error lay with my rendition

of the original AB763 schematic. The vibrato channel has an extra gain stage

due to the loading effect of the reverb and tremolo circuit. The tremolo pot

puts a 50K resistance on the signal path just prior to the mixing resistors

that feed the PI. I had totally omitted this resistor! Gator clipped a

resistor in and everything quieted down. The final fix is

a 100K pot for a master volume control. I'll just give up the 'Middle' tone

control. |

After debugging, I spent 4 hours with my strat tied to

this thing! I couldn't leave. It felt good. It sounded good. By the time I

realized I needed to move on, I'd celebrated too much to do any more work.

The cab work could wait 'til tomorrow. Anyway, I just thought of another tune

to try! |

|

Almost heaven... It's tomorrow! Imagine my

joy when this chassis slipped snuggly between the side cleats in this cab!

Actually, this point was my biggest research

challenge. I posted the question "what is the exact distance between cleats"

in several different places.... Mission Amps, Mo Jo, Weber, and on AGA. I

got a variety of responses, but no one could give me a measurment. Well,

actually, one guy on AGA nailed my question with real numbers, but by this

time, I had charged ahead and bought the cab from Marsh Amps on eBay. I'm

pretty sure he's sourcing from Mo Jo. I knew it would be within 1/2'

and was prepared to modify the cleats to make my chassis fit. I was

pleasantly surprised.

There are only a few things left to do now, 1) Shellac

the cab, 2) make a faceplate, and 3) get a speaker.

Shellac is done. I applied 4 coats of Zinsser's Amber

cut 50/50 with denatured alcohol.

As

it turns out, the speaker selection is going to be limited. There's not much

room in that cab. I'll either have to stay with the one I borrowed from the TRRI or find a suitable low profile model. |

Almost done. It's been a challenge to fit everything from

the onset. As you can see, putting it all in the box was no exception. But

my friends, you're looking at the genuine original, one of a kind, AB763

Tweed Deluxe Reverb. Who

cares? Probably no one. And certainly not me. Hey, I got one! What a trip!

As you can see, the speaker selection is done. I chose

the Jensen P12N reissue. It has a much brighter sound than the borrowed

C12-K from my TRRI. |

I guess a home brew is never quite completed and I doubt

this will be any different. I still have a couple ideas to try while the adrenalin is

flowing. And I may upgrade the iron. But this was never a quest for the ultimate

amp. It ain't the arrivin' but the gittin' there that turns my crank. And I sure

had one sweet ride!

Thanks for listening....Steve Luckey (aka 57chevy) . . . . January 21, 2006

Update (April 22, 2006)...

Well, I guess you knew I couldn't let it be. And I knew

it too! I really enjoy playing through this amp, but I love tinkering under

the hood.

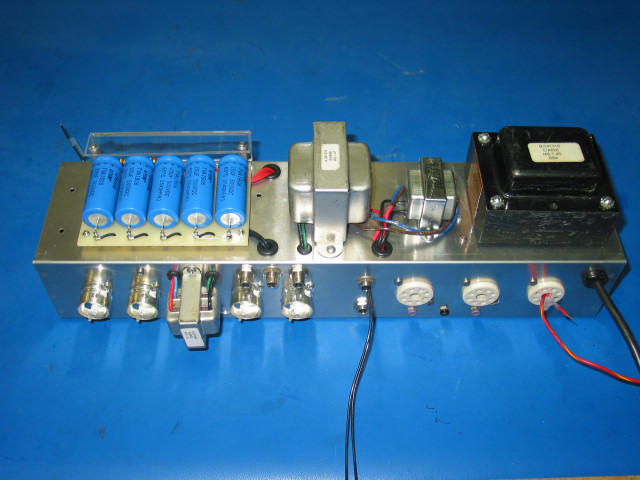

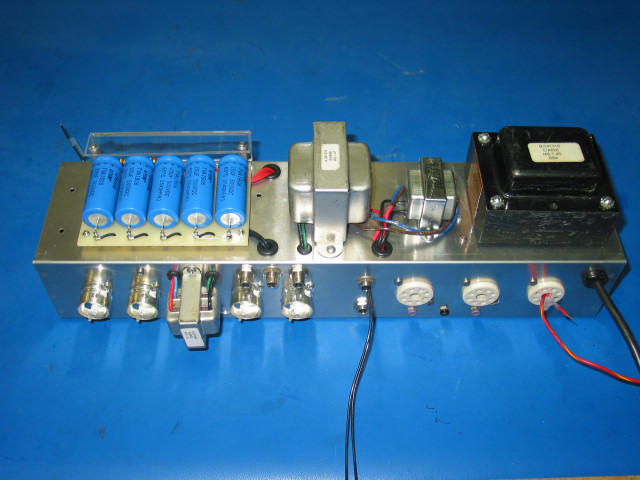

So I made some major changes. All the iron has been

upgraded to Mercury Magnetics and I've switched to 6L6s for the output. I'm

currently running on borrowed Groove Tubes from my TRRI but will be changing

to JJ Teslas before the end of the week. With the bias set for 46 milliamps

and the plates at 394 volts, the static plate dissipation is 18 watts. This

amp truly is a prime example of a wolf in sheep's clothing!

The sound is fuller on the bottom and the sparkle is

still there on the high end. I don't think I'll be switching back to the

6V6s anytime soon.

While I was under the hood, I removed the

Pentode/Triode switch. That was a nice toy to play with, but after a month I

found I was just leaving it in the Pentode position. An external speaker

jack now occupies the vacated switch hole.

I'm still waiting for a faceplate. A local trophy shop

says they can do it but with spring sports season in full swing, they're too

busy for now. Meanwhile, I've used Visio again to create and print my own.

It looks OK printed on photo paper but is not very durable.

(June 28, 2006)...

The 6L6 JJs have been running fine for over a month

now. I finally dropped the idea of a faceplate. I polished the front panel

to a 'near' mirror finish and used white dry transfer lettering. Looks good!

Oh, and I've replaced the Jensen P12N with a Weber

ceramic California.

The 'Tweed Deluxe

Reverb' is done!

I hope I get as much enjoyment from playing this amp

as I did from building it.

Epilog (July 1, 2006)...

I had so many extra parts left over from this project

(transformers, speaker, tubes, etc.) that it seemed a shame to just stick'em in a

box. But that's exactly what I did....sorta!

Take a look ...

Lil Sister

|

The wolf in sheep's clothing! Still looks innocent enough. The

Weber shines through.

Popping the hood reveals the super charged drive

train.... All Mercury Magnetics iron driving JJ 6L6s which in turn drive a

Weber California!

Tight control panel.

The wolf! MMs and JJs pump out 28-30 watts of unclipped

power into the new Weber Cali.

Still an AB-763, although I now hesitate to call it a

Deluxe Reverb.

|

Download the

schematic and board layout

Return to Index

|