|

updated May 10, 2014

1960 Vox AC-15

In

the summer of 2012 Bnwitt started a discussion at Hoffman's Amp forum. He

proposed to build a 1960 Vox AC-15 for his studio. His idea was to develop a

layout for a single chassis, Marshall style amp. The unique vibrato circuit of

this amp has intrigued me for a long time. Soon I was caught up in Barry's idea

and began corroborating with him on this project. We swapped many ideas back and

forth, but soon realized we were headed two different directions. He wanted to

use two boards and keep a similar tube layout and control panel layout kinda

like the original, but put it all on a single chassis. I liked the idea of one

single board, tubes lined up across the back like a Marshall, and rearrange the

faceplate to fit the board layout. Barry soon became busy with his real life and

dropped off the forum. I don't know if he ever completed his project, but he's

to blame for my interest in the AC-15. I completed my layout but set it aside

and got busy with house remodeling and planning my retirement at the end of the

year. The AC-15 idea had faded. In

the summer of 2012 Bnwitt started a discussion at Hoffman's Amp forum. He

proposed to build a 1960 Vox AC-15 for his studio. His idea was to develop a

layout for a single chassis, Marshall style amp. The unique vibrato circuit of

this amp has intrigued me for a long time. Soon I was caught up in Barry's idea

and began corroborating with him on this project. We swapped many ideas back and

forth, but soon realized we were headed two different directions. He wanted to

use two boards and keep a similar tube layout and control panel layout kinda

like the original, but put it all on a single chassis. I liked the idea of one

single board, tubes lined up across the back like a Marshall, and rearrange the

faceplate to fit the board layout. Barry soon became busy with his real life and

dropped off the forum. I don't know if he ever completed his project, but he's

to blame for my interest in the AC-15. I completed my layout but set it aside

and got busy with house remodeling and planning my retirement at the end of the

year. The AC-15 idea had faded.

Then this winter lego4040 contacted me with some questions

about my layout drawings. He was excited about building this amp. He helped me

refine the layout by pointing out some inconsistencies between the different

drawings and in doing so, inspired me to revive my own interest. And when I saw

his board come to life from my drawings, I was hooked. I had said I was through

building amps, but here I go again. Lego, it's really your fault!

My original design incorporated a Fender style cap board and doghouse. One

day while playing Visio, I realized I could use one dual cap can, stretch the

main board a little bit, and eliminate the separate cap board, and still have a

clean layout. This idea became the final plan and is what I used to build my

amp.

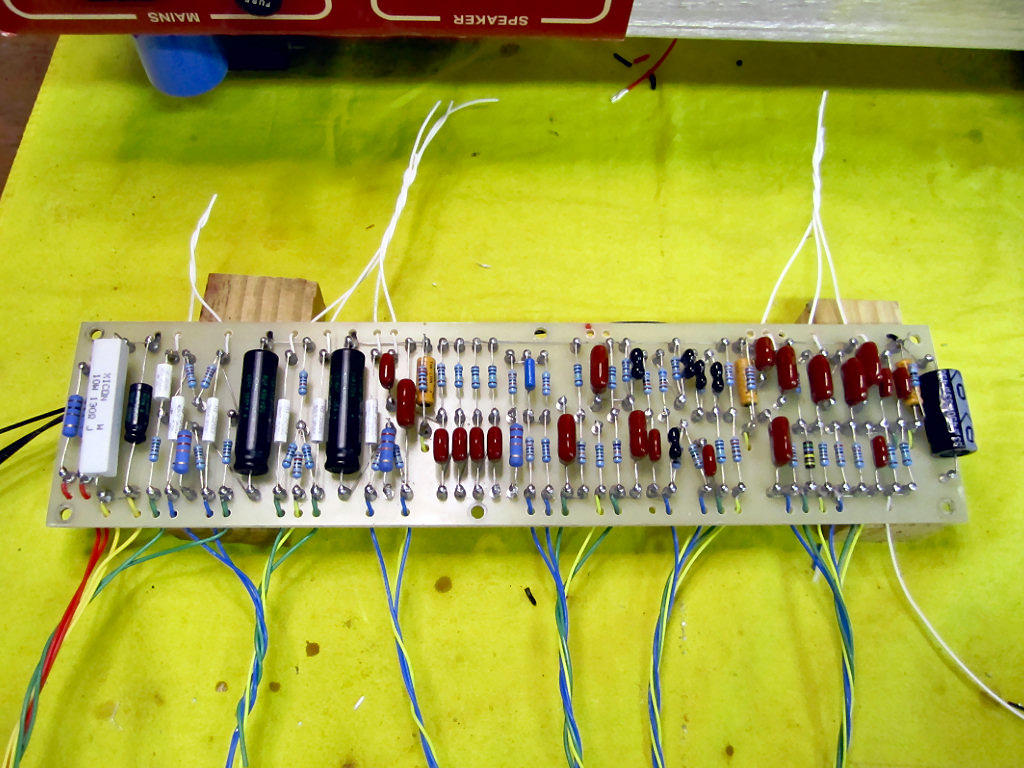

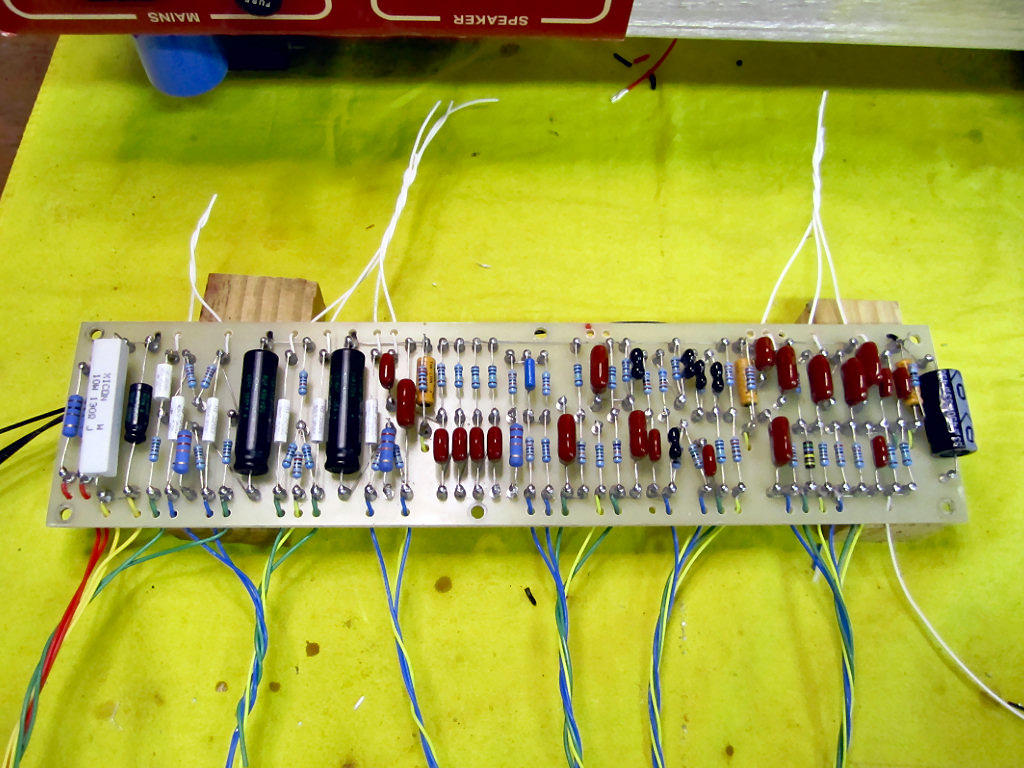

This was to become my most ambitious project to date. For

a seemingly simple amp, the 1960 Vox AC-15 has a higher parts count than any amp

I've built. And my logical but unproven layout required more planning than my

other projects. The jam packed board had to be right and have a logical flow for

component locations. And there are a lot of jumpers that must be in the right

places too.

The board layout, tube lineup, and control panel had to

fit together as a unit. All other components were arranged to accomodate this

unit. Slowly it came together on screen. I really enjoy the planning phase, but

the actual construction has a lot of tangible rewards mainly because now you

begin to see and feel your project and you know it's real.

Even though the circuit remained true, the layout design

stepped way out of the Vox box and I remained cautiously skeptical right to the

end. But all that went away when I finally flipped the switch. A few preliminary

voltage checks and I was wailing away in under 5 minutes. The amp is quiet when

it should be and sounds nice when you're playing. The tremolo is very deep and

smooth and rivals the Fender

harmonic tremolo in my Revibe. And the Vibrato is really a true pitch shifting

vibrato, although it only has a single modulation stage and is not as intense as

I would like. It sounds very nice,

but not as nice as my Magnatone M10-A dual stage vibrato. The Vibrator channel

is brighter than the Normal channel. The Normal

channel has that nice EF86 sound that you would expect. It's also much louder

than the Vibrator channel.

So, all that planning paid off. The layout is a proven

winner. I'm really pleased with the way this project turned out.

The following pics appear in the same order as the build progressed. Enjoy...

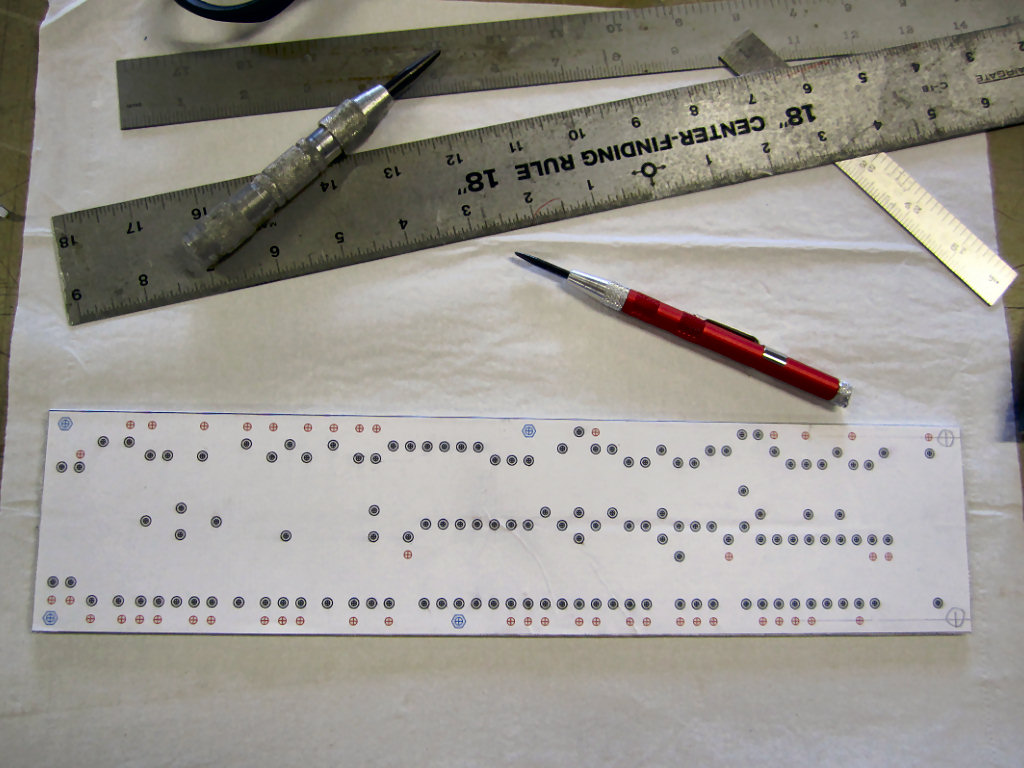

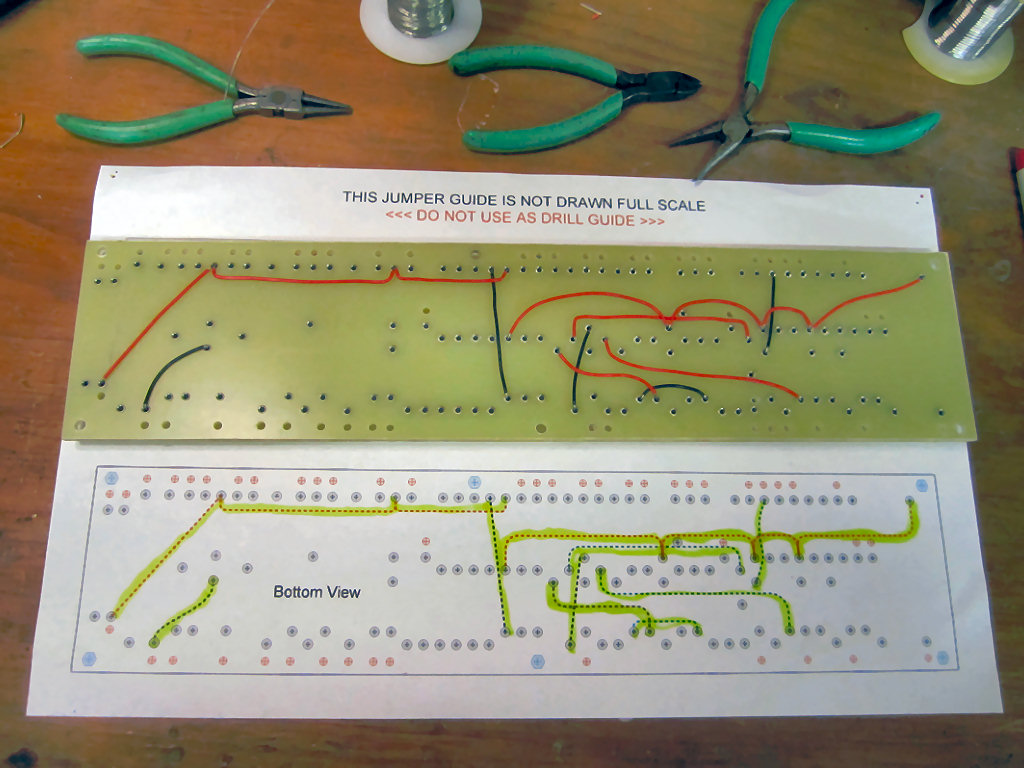

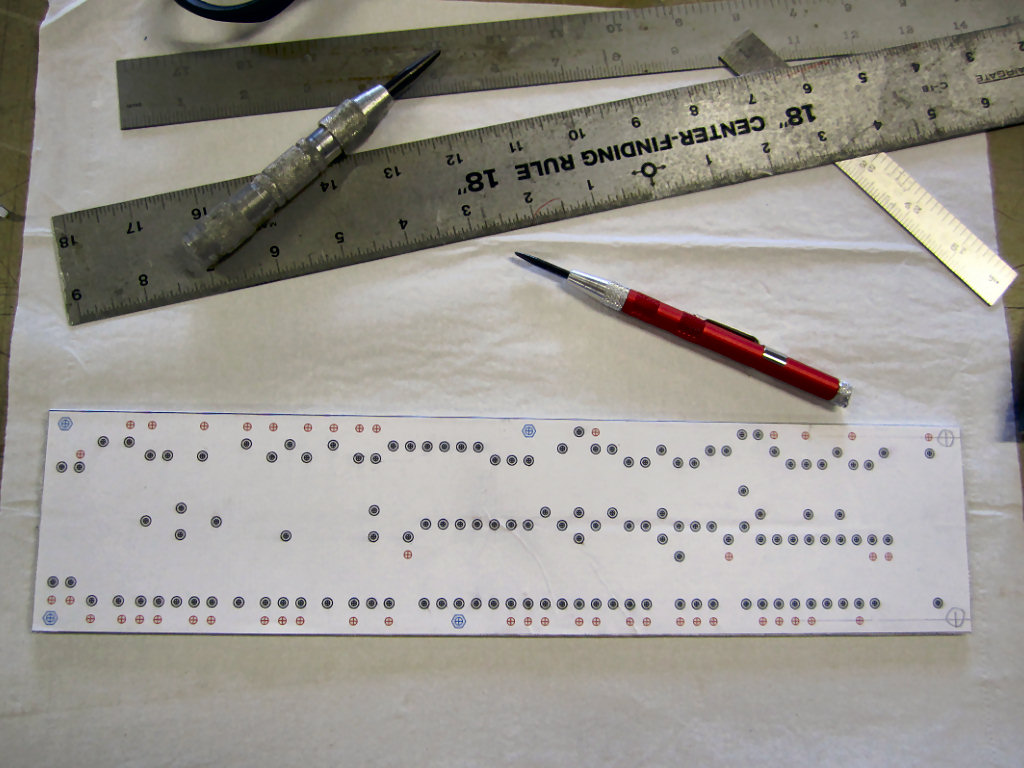

The drill guide is taped to the board using double sided

carpet tape. It's ready to be center punched and drilled. There are a lot of

holes on this board and it can be confusing concerning which hole is for what. I

drill the larger standoff holes (blue) to proper size first, then switch to a

1/8" bit to drill the wire passthru holes (red). Finally, I use a 3/32" bit to

drill all the turret holes.This method works well for me and when I start

loading the turrets if I accidently put a turret in a wire passthru hole I will

know immediately because it will be a sloppy fit.

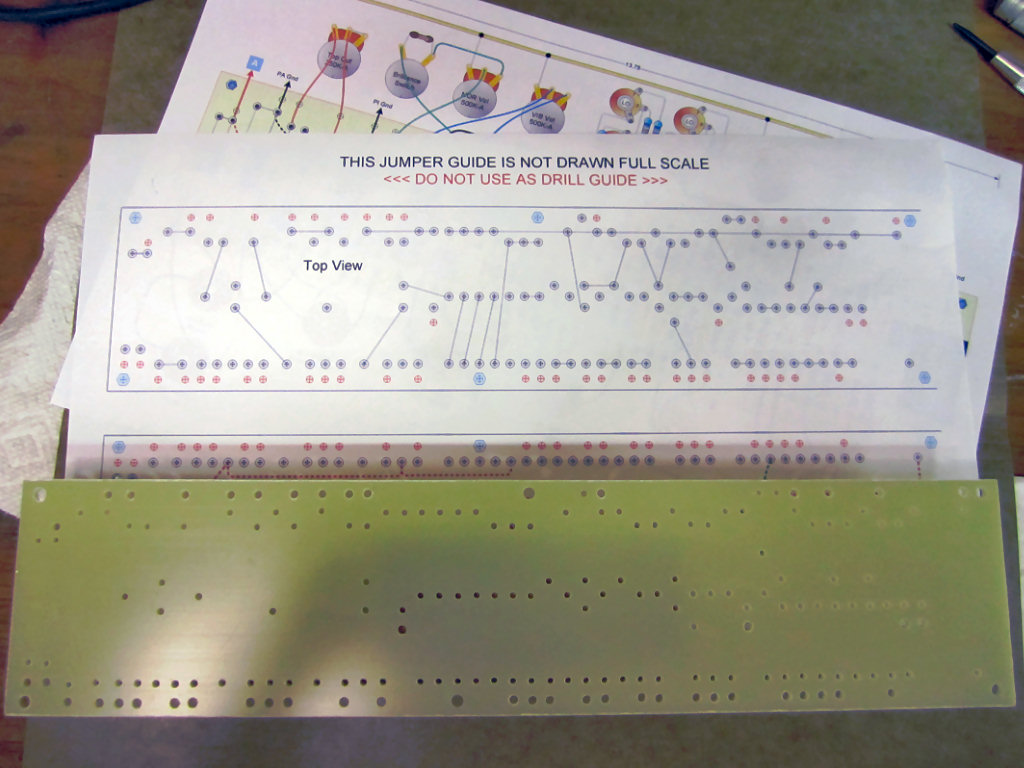

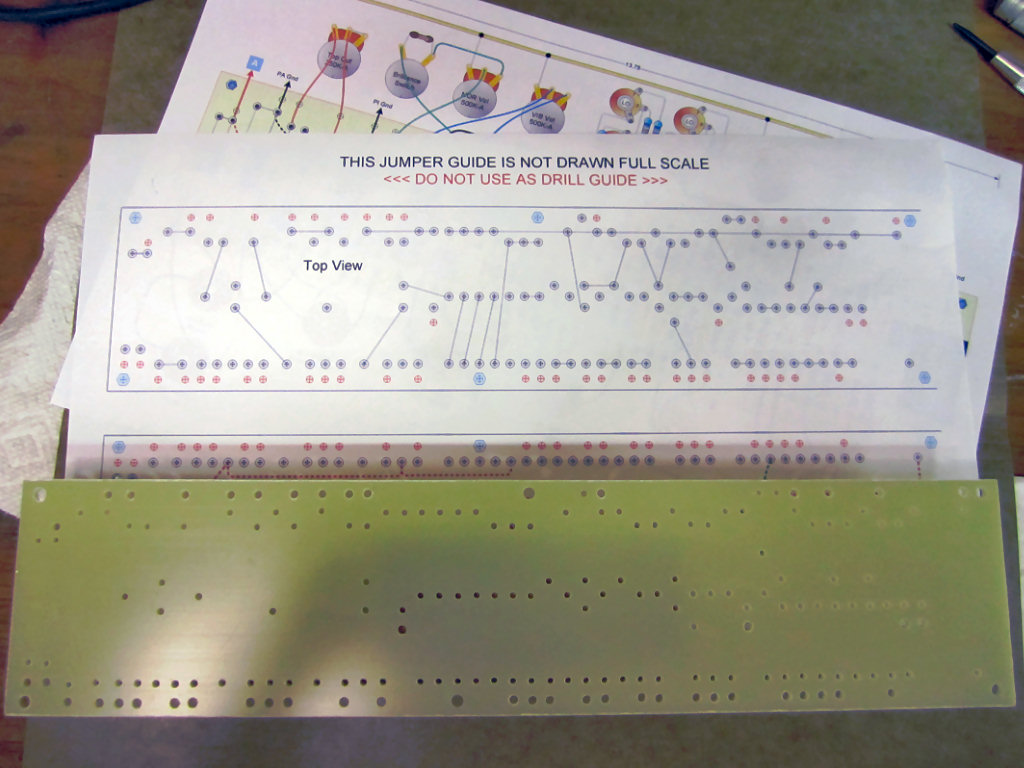

The board has been drilled and now it's time to load the

turrets. Notice the turret holes are smaller than the wire passthru and standoff

holes.

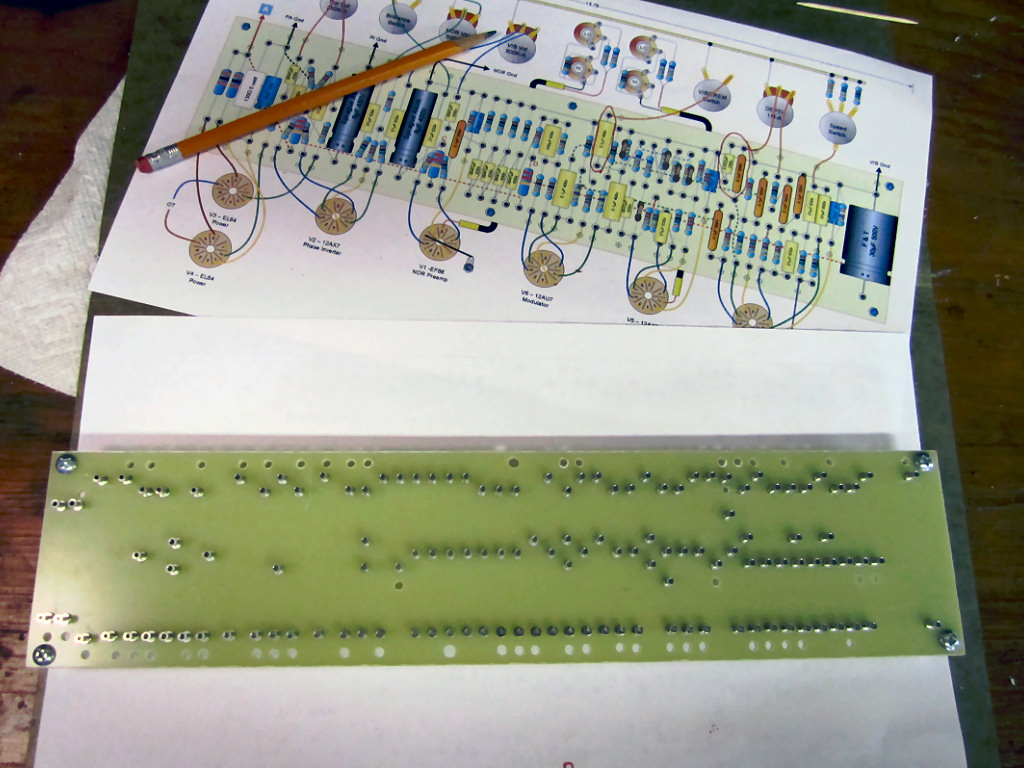

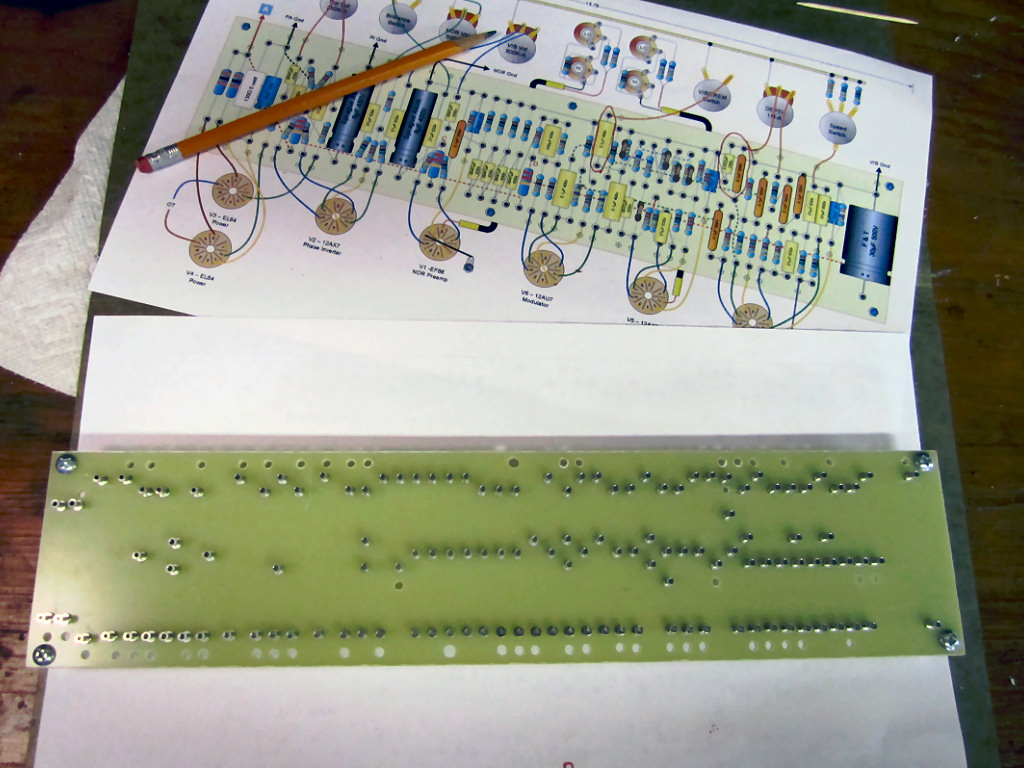

Turrets are installed using a drill press and staking tools

available from Hoffman.

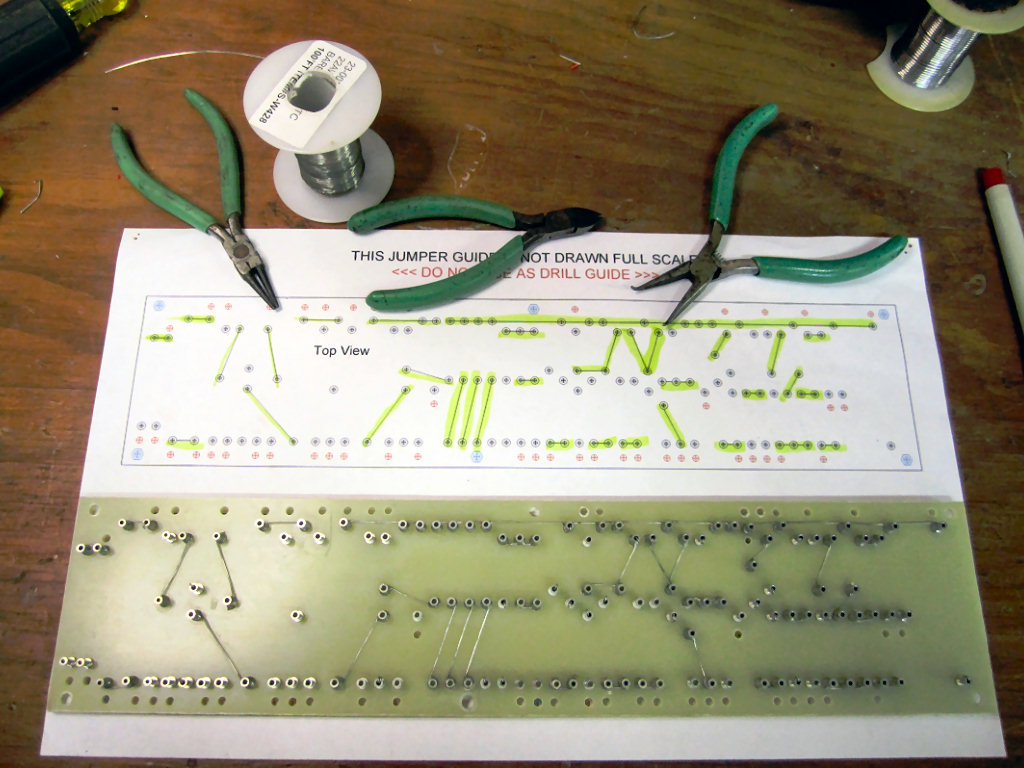

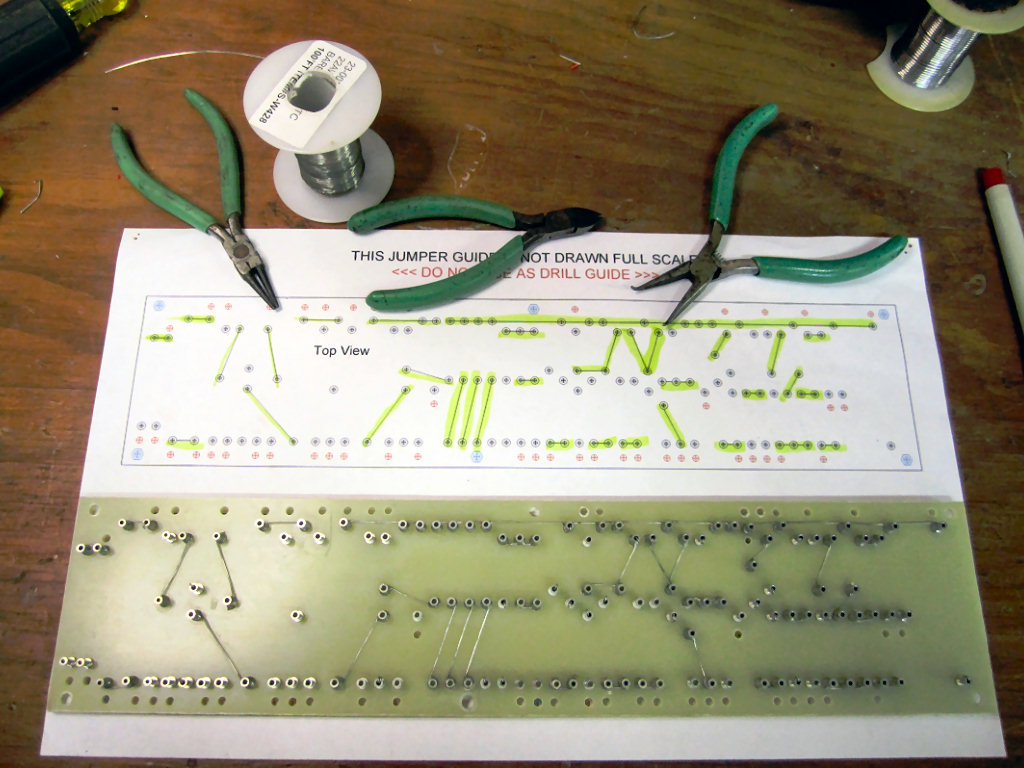

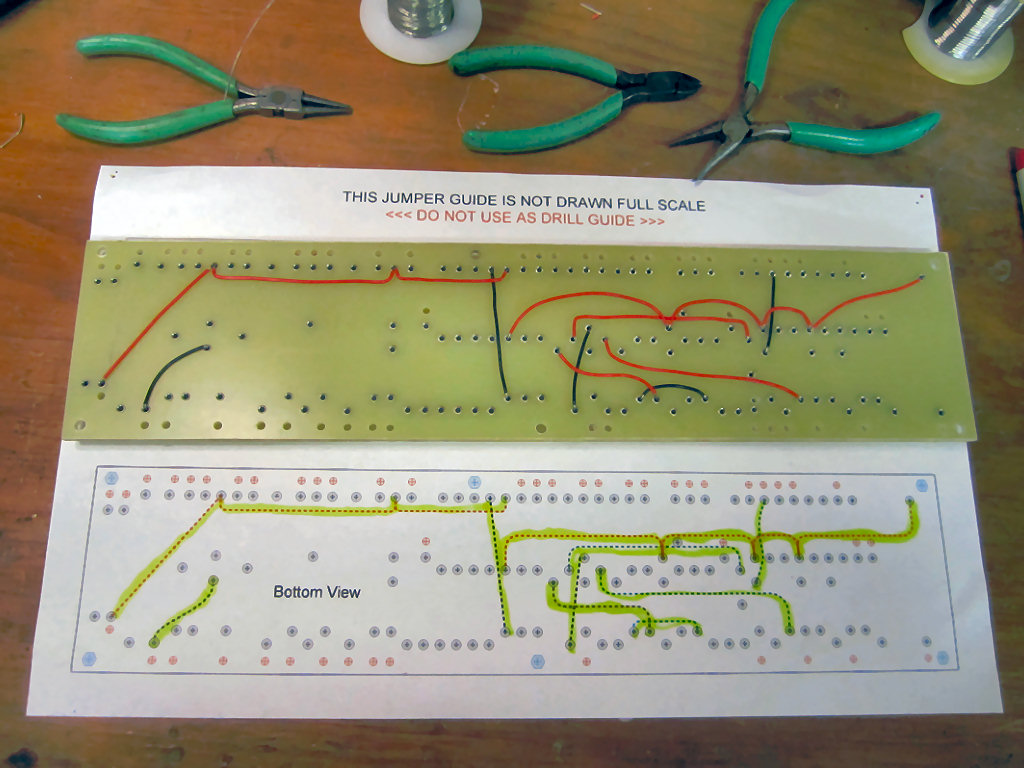

Lot of jumpers on this board. I use a highlighter to mark the

jumper guide as I go.

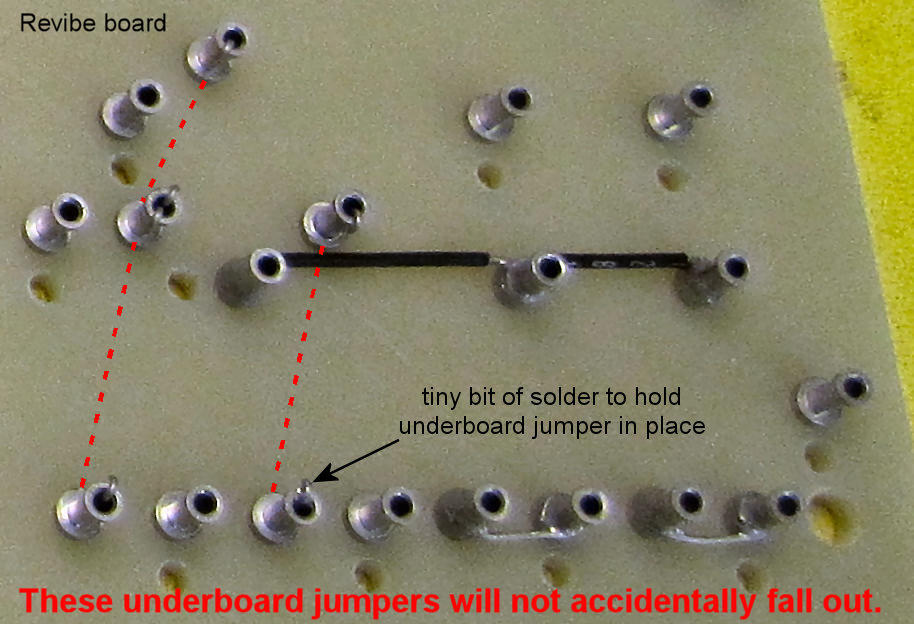

Same for the underboard jumpers. A mistake here will cause a

lot of grief later on.

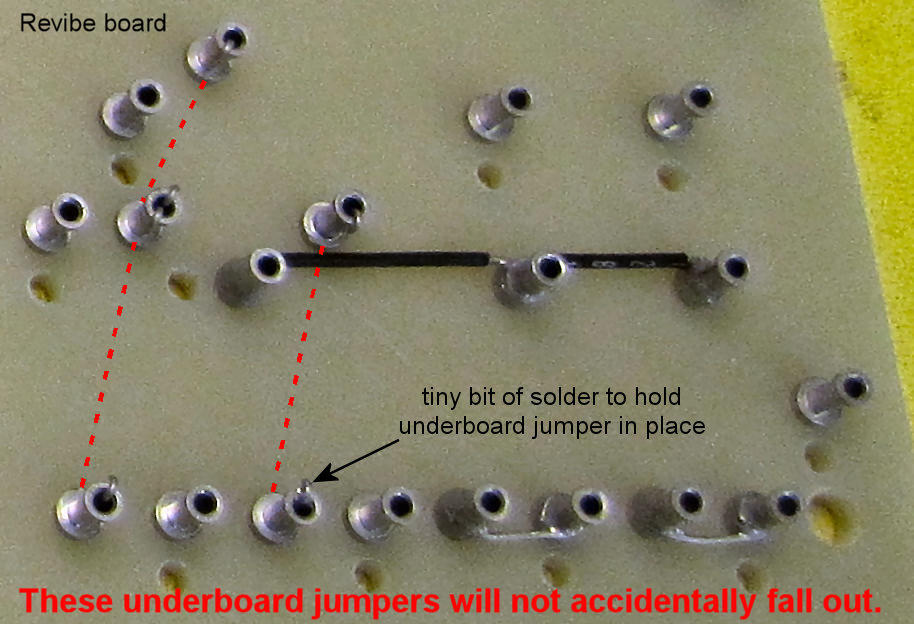

I don't like using underboard jumpers but sometimes it's

unavoidable with a complicated board. When I do use them I want to know they

will stay in place securely. So, I always push the end of the jumper completely

through the turret and 'hook' the end back over the outside of the turret. This

little detail allows you to see the jumper even after soldering, but more

important, it prevents the jumper from falling out of the turret whenever you do

any later soldering.

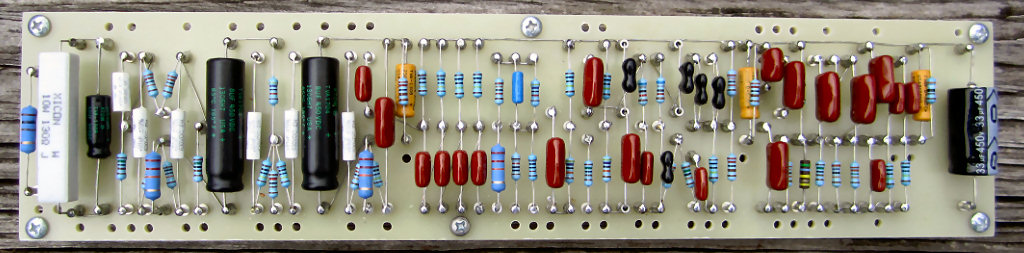

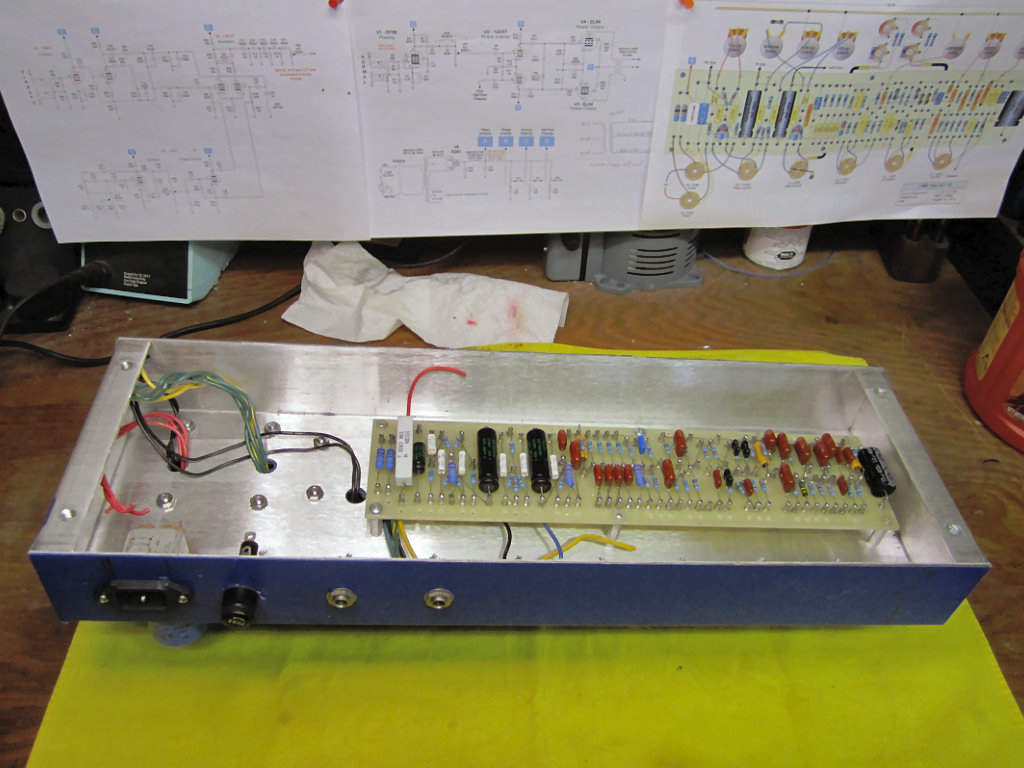

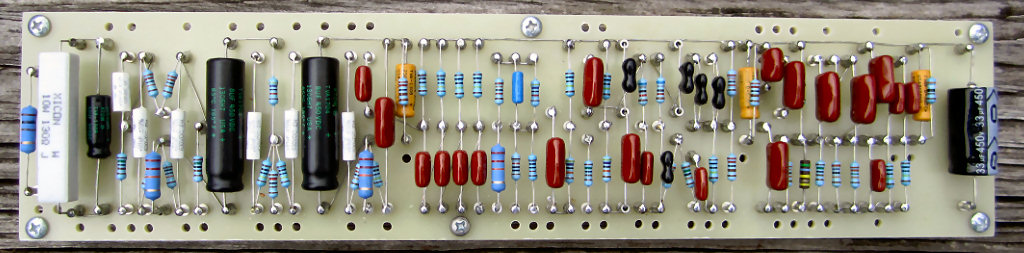

And here's the loaded board. I sure hope it's right!

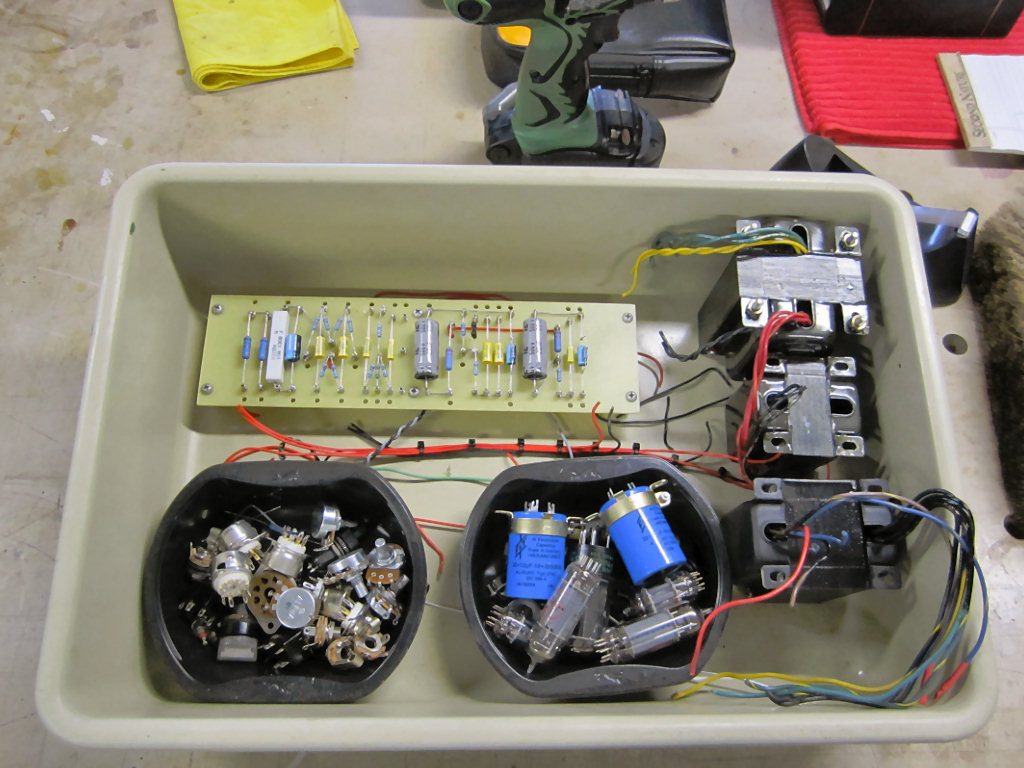

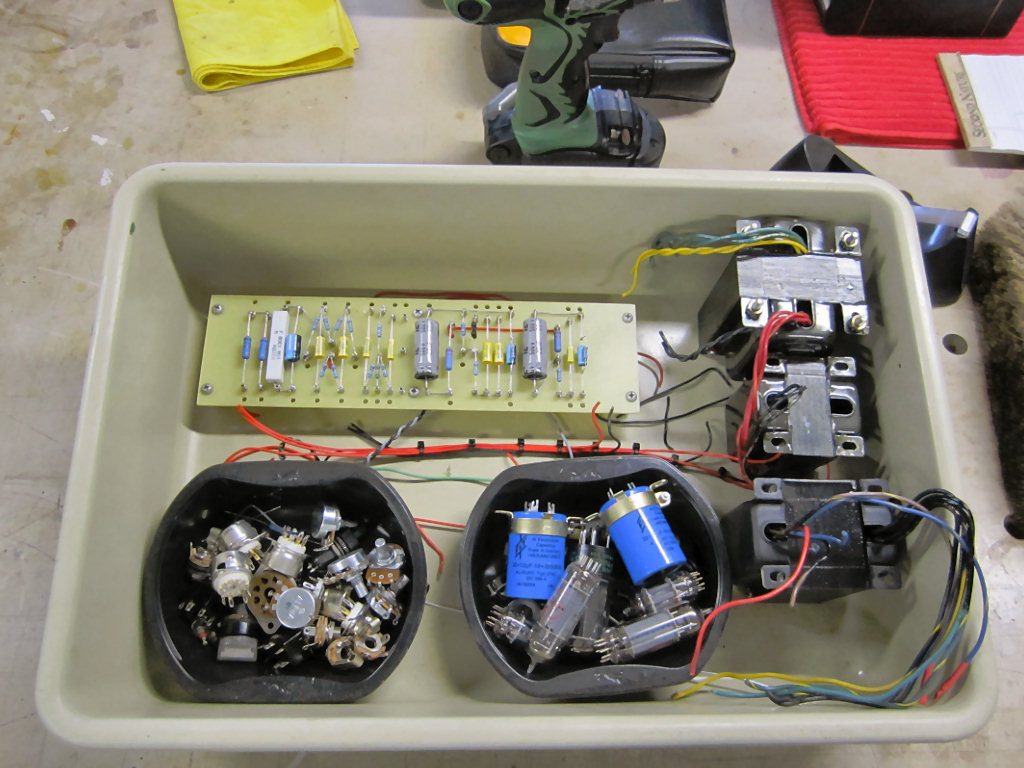

My Matchless Lightning became a donor for this project. A lot of these parts

will go into the AC-15 chassis.

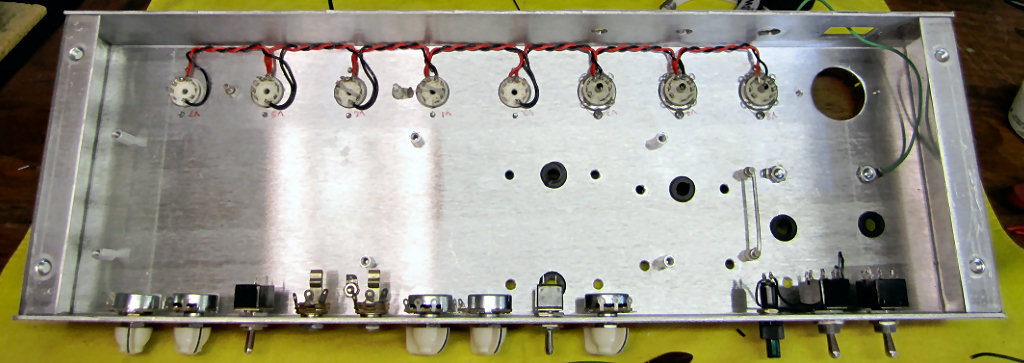

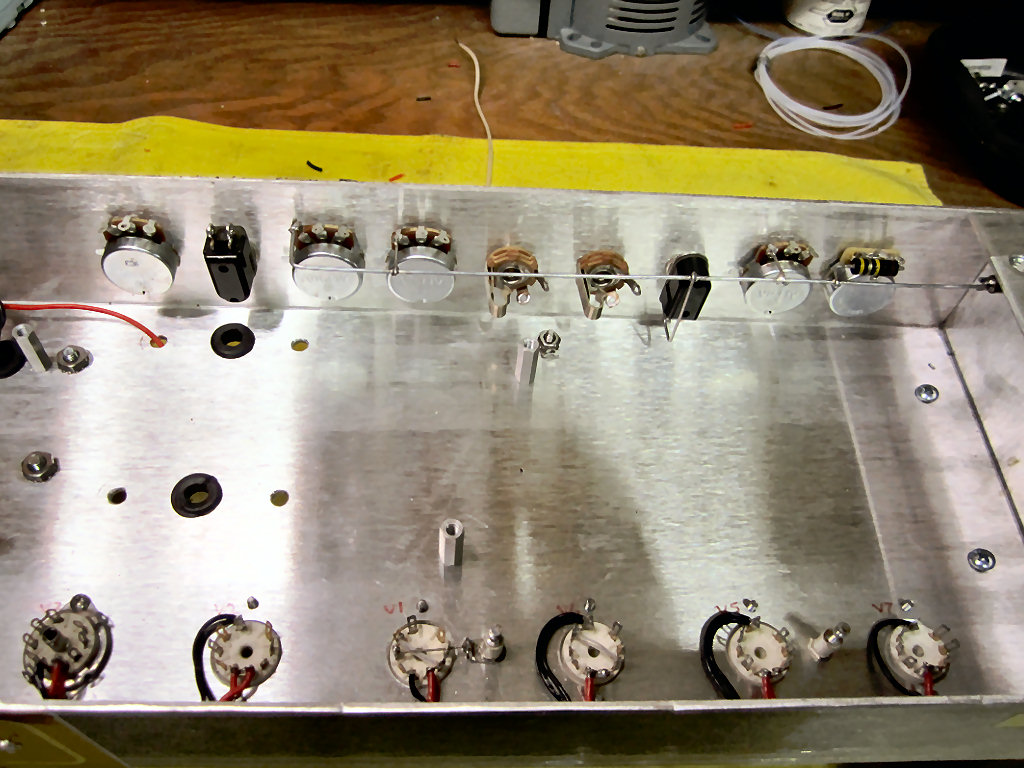

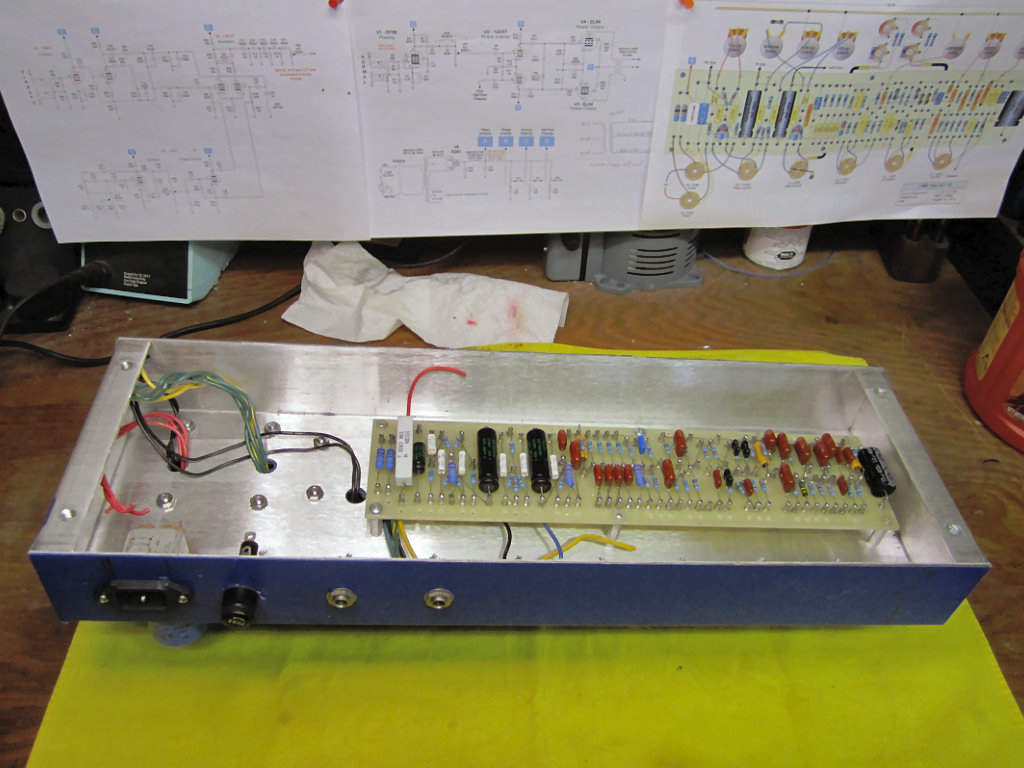

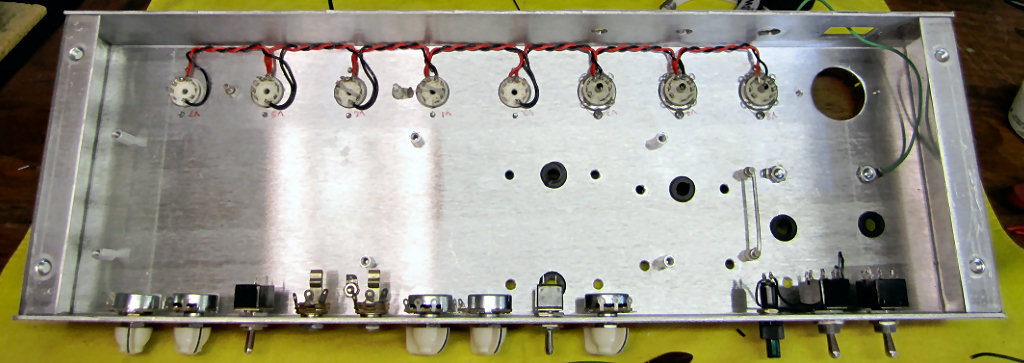

I got the chassis from turretboards.com. It's thick enough

that I was able to tap with 4-40 and 6-32 to secure the tube sockets and cap

clamp. Most of the drilling is done for the top of the chassis.

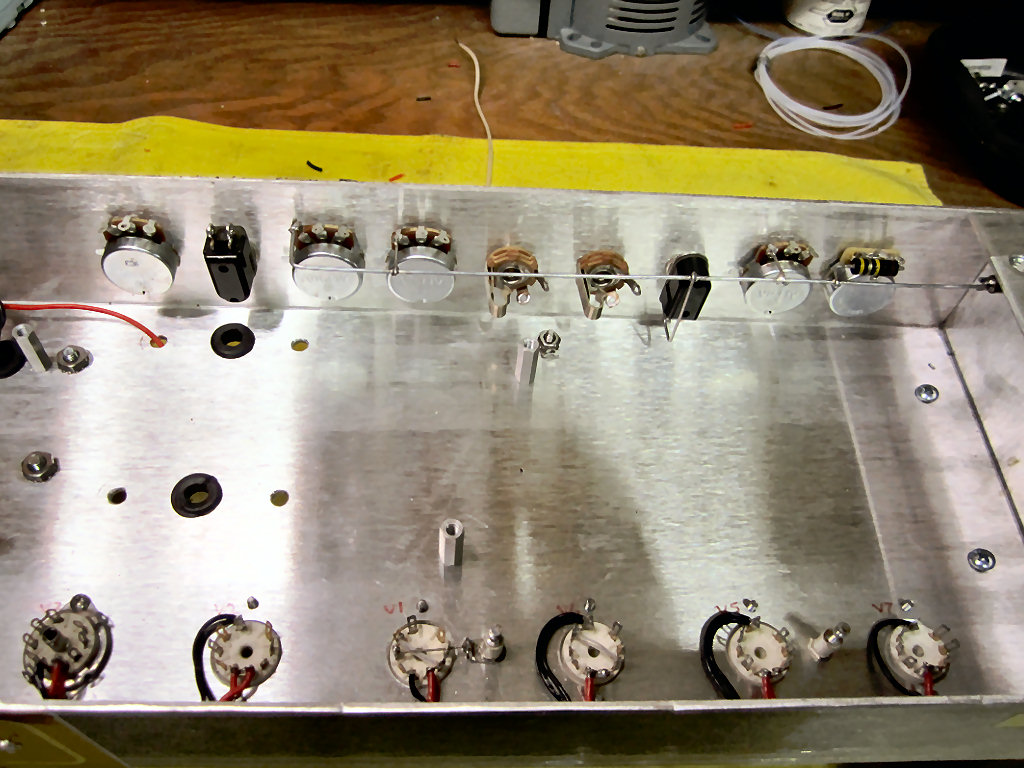

Beginning to look kinda Marshally now.

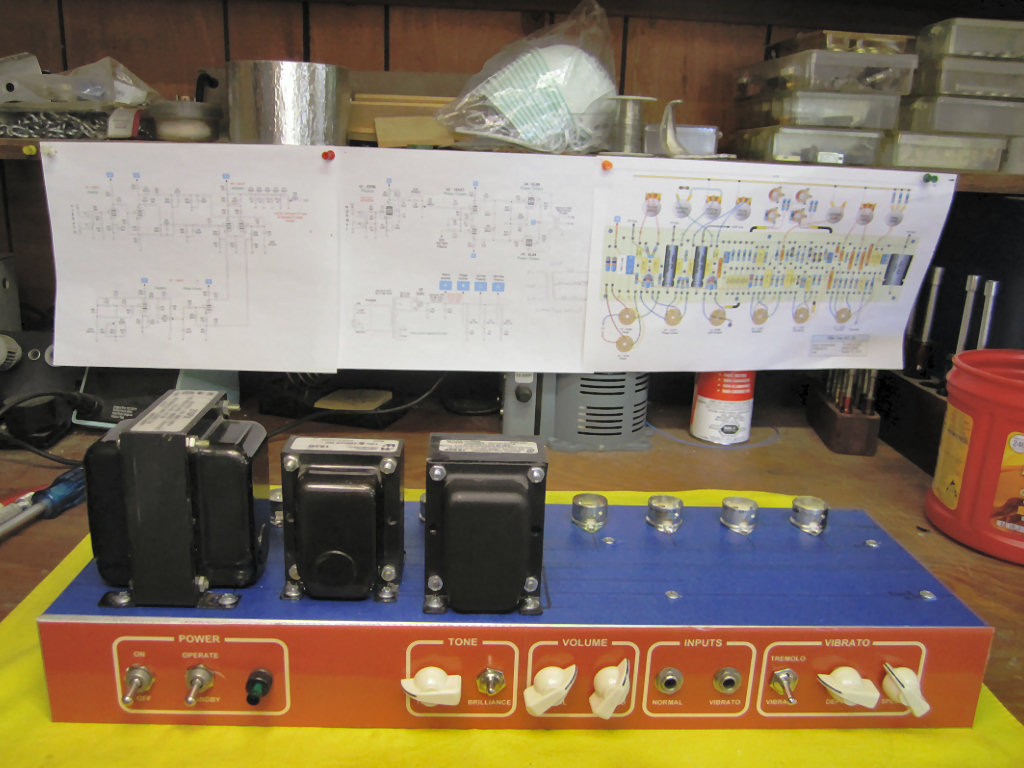

Rear panel is drilled and components fitted.

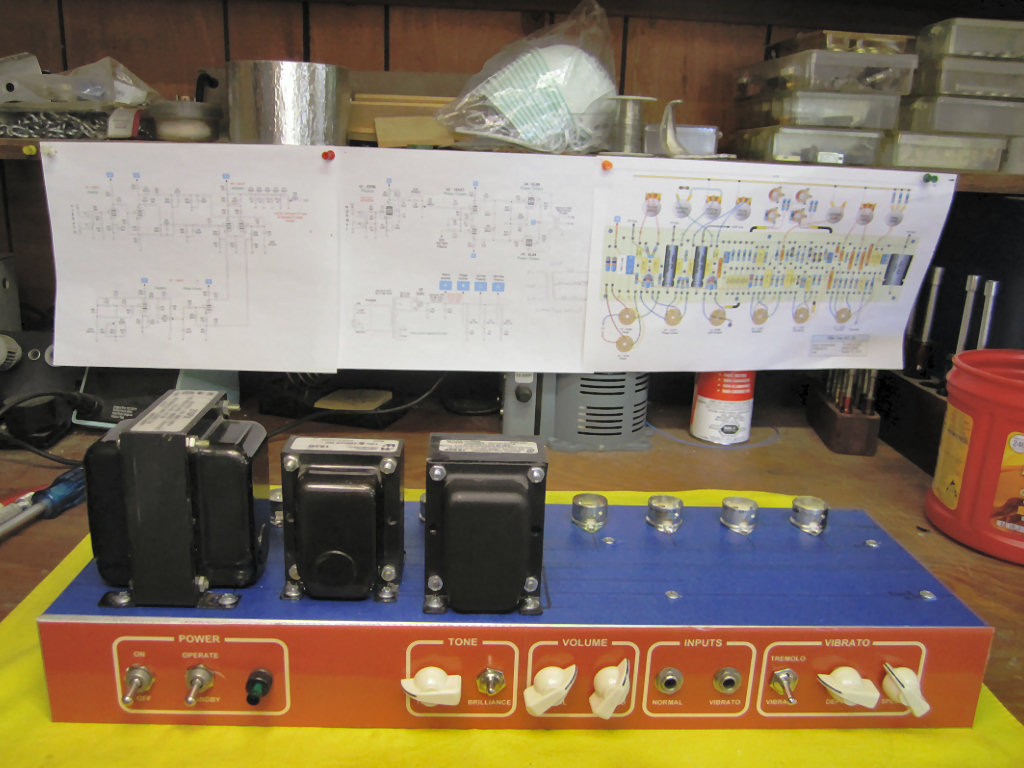

And the front panel is drilled and loaded. I even have a poor

man's faceplate. Looks like an amp now.

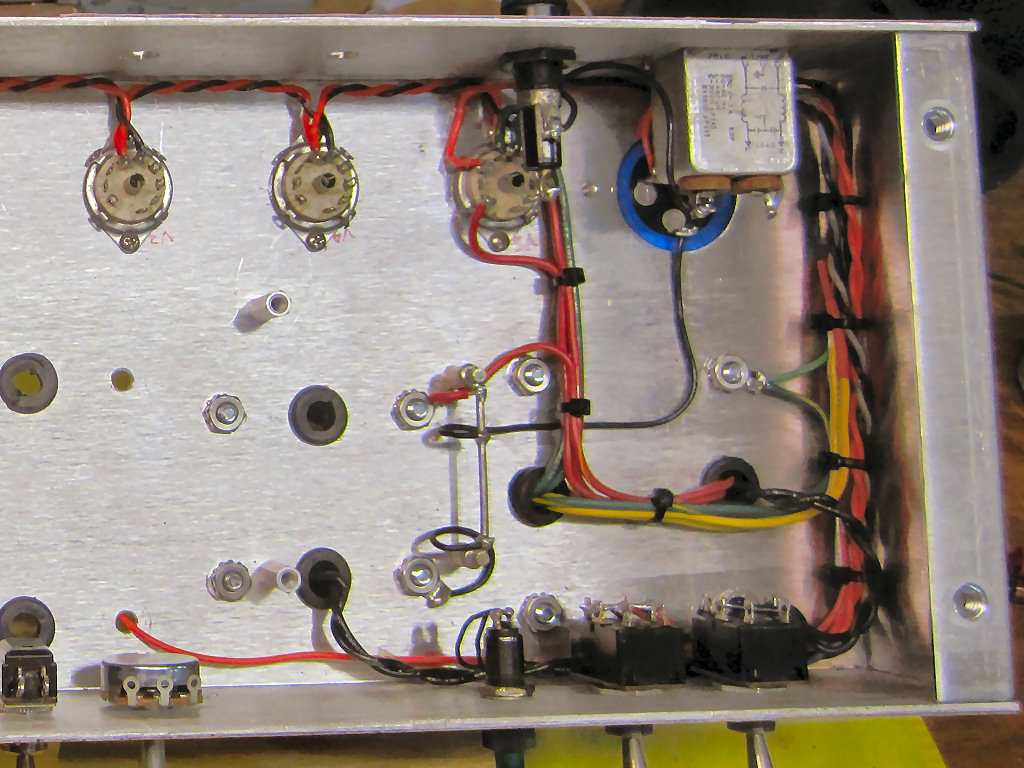

Filament string wiring comes next.

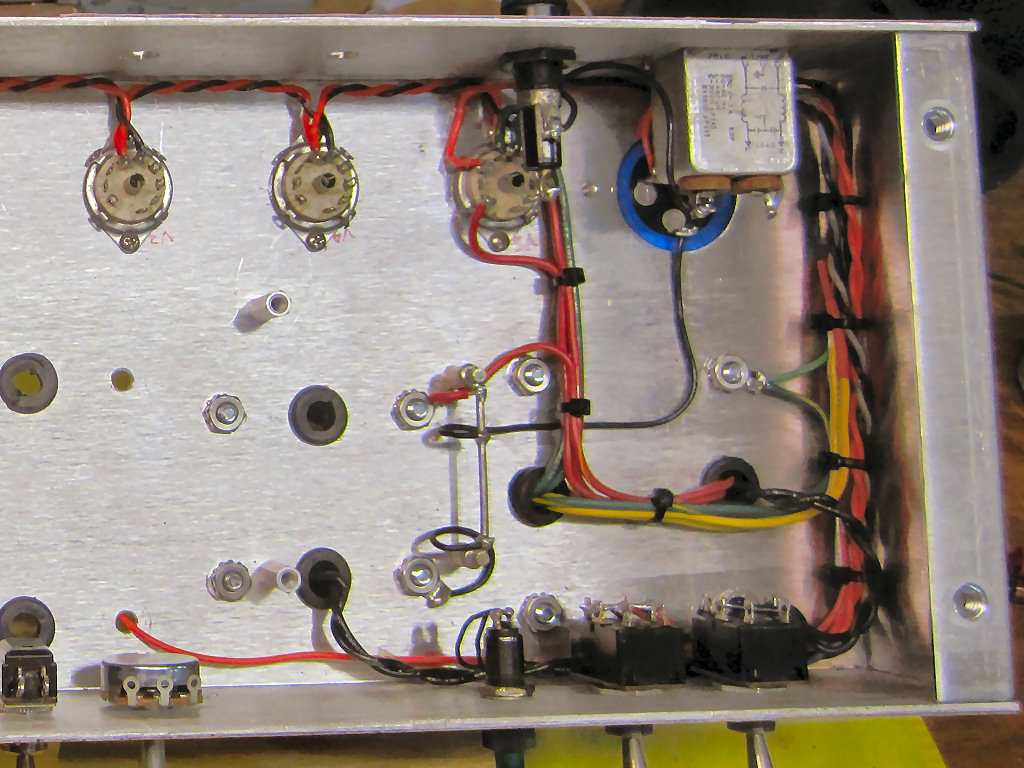

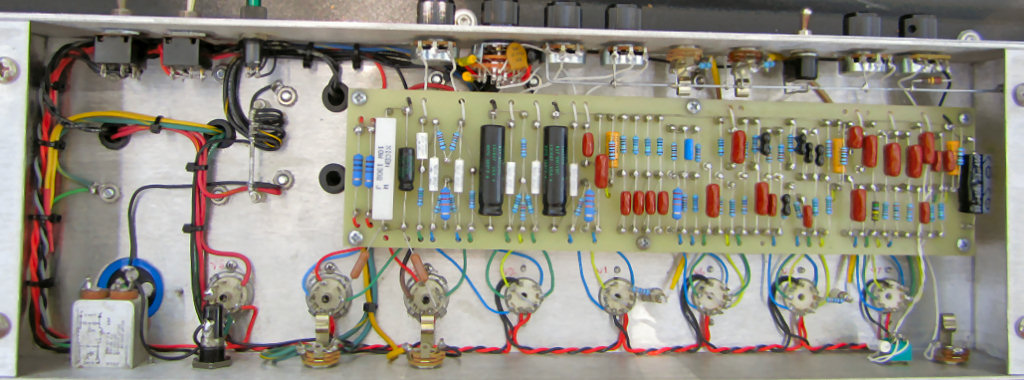

And the power supply is wired and has been tested at this

point. Notice the ground buss.

The ground buss for the control panel has been installed. It

will attach to chassis with a lug directly under the input jacks.

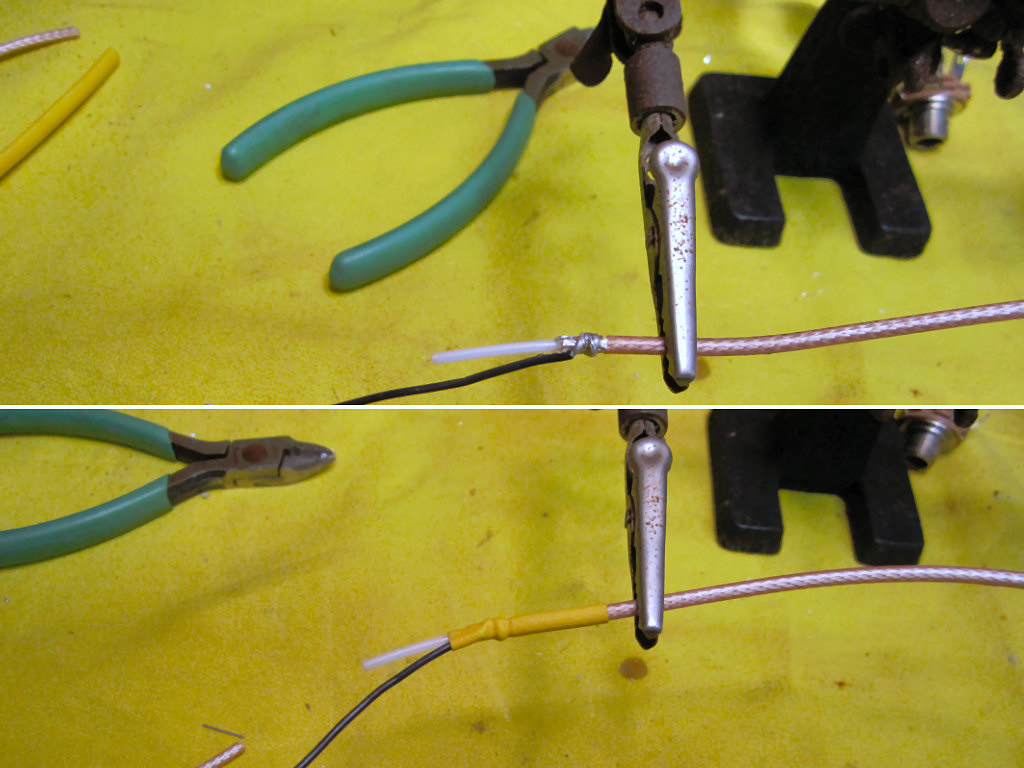

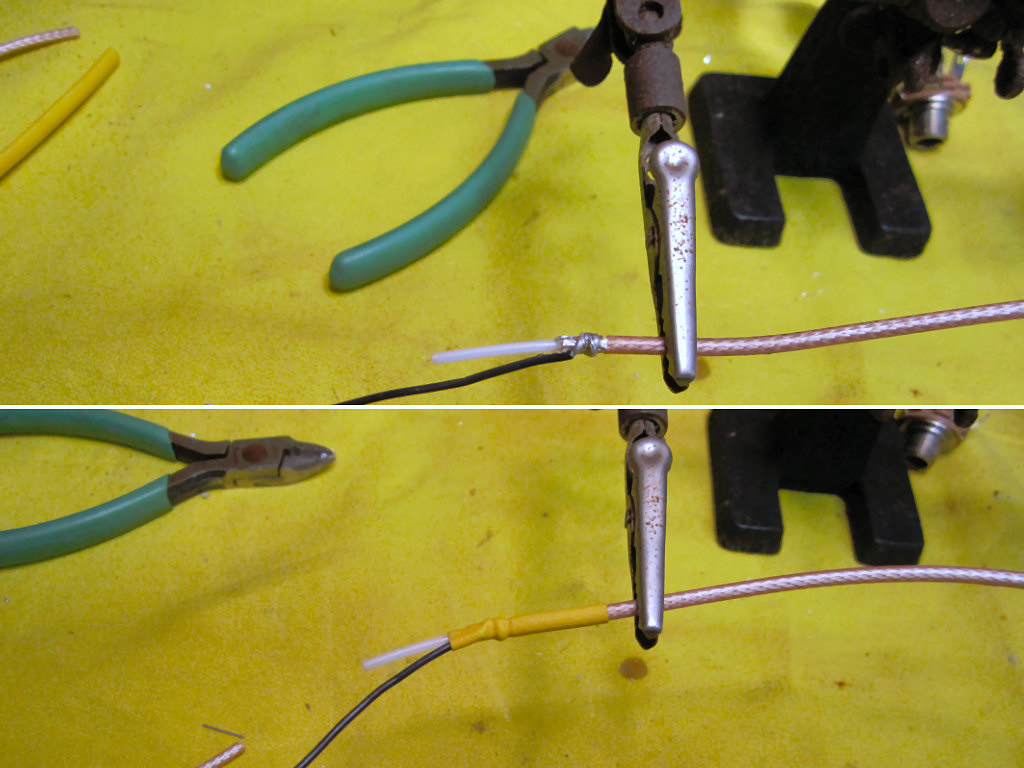

I like to use RG-316 for input connections. The PTFE

insulation make it very easy to work with. Don't try this with RG-174.

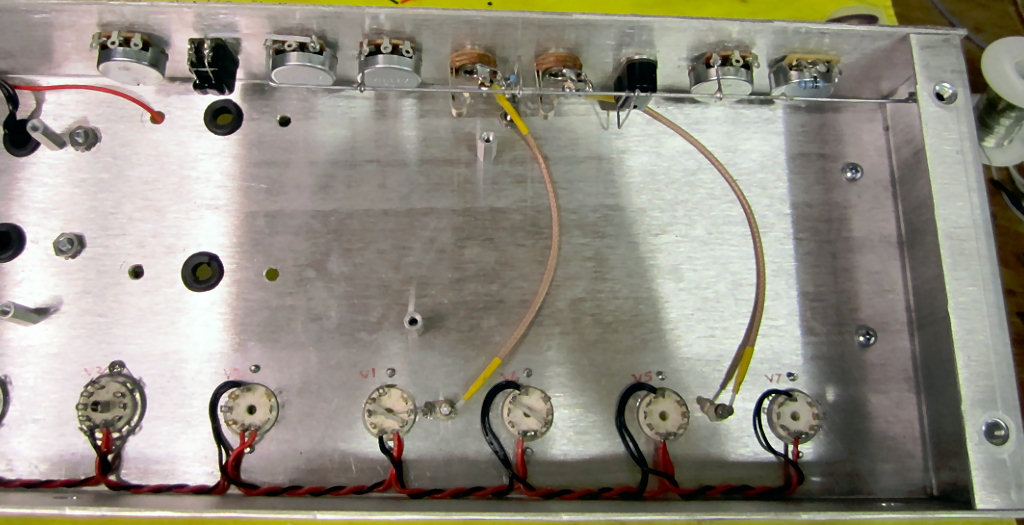

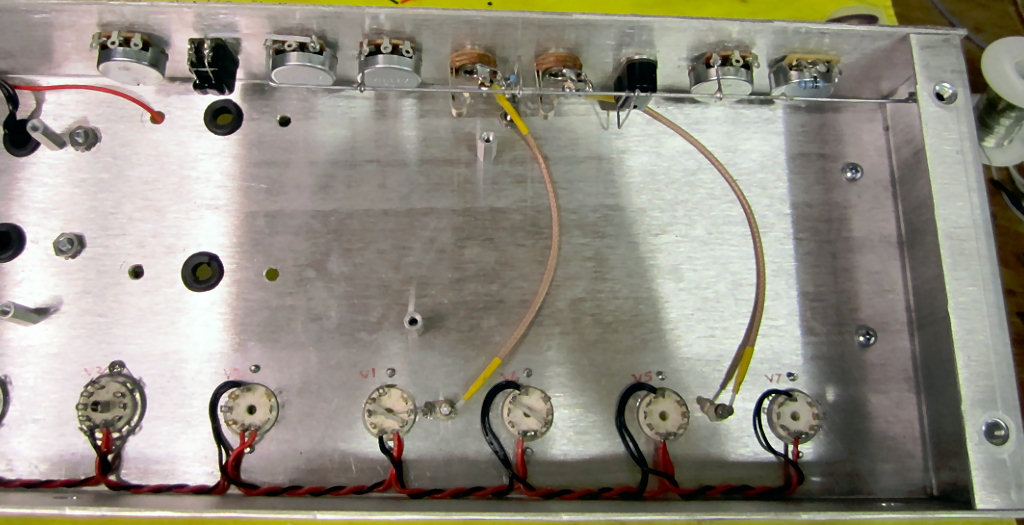

The input jacks are connected. Next the OT was installed but

I forgot to take a picture.

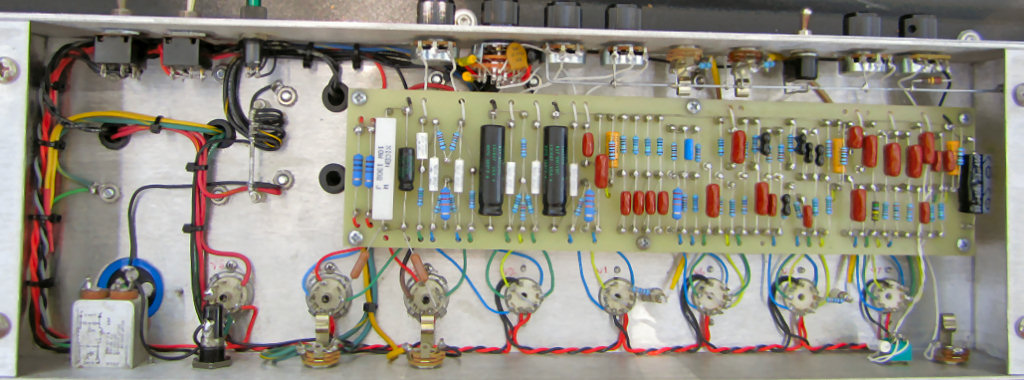

The interconnecting wires are in place and the board is ready

to be permanently installed.

Done! (Click for a closeup view)

Front view.

Rear view.

Thanks to Ed I actually have a real faceplate. That's a first

for me! I had to lose the chicken heads because they were too close and were

constantly fighting.

Download my full size board layout, drill

guide, jumper guide, ground scheme, schematic, and more in a single PDF.

Vox AC15.pdf (914KB)

These mods are a nice addition to the stock

AC-15. I have tested all of these on my amp.

Vox_AC15_mods.pdf (324KB)

Return to Index

|  In

the summer of 2012 Bnwitt started a discussion at Hoffman's Amp forum. He

proposed to build a 1960 Vox AC-15 for his studio. His idea was to develop a

layout for a single chassis, Marshall style amp. The unique vibrato circuit of

this amp has intrigued me for a long time. Soon I was caught up in Barry's idea

and began corroborating with him on this project. We swapped many ideas back and

forth, but soon realized we were headed two different directions. He wanted to

use two boards and keep a similar tube layout and control panel layout kinda

like the original, but put it all on a single chassis. I liked the idea of one

single board, tubes lined up across the back like a Marshall, and rearrange the

faceplate to fit the board layout. Barry soon became busy with his real life and

dropped off the forum. I don't know if he ever completed his project, but he's

to blame for my interest in the AC-15. I completed my layout but set it aside

and got busy with house remodeling and planning my retirement at the end of the

year. The AC-15 idea had faded.

In

the summer of 2012 Bnwitt started a discussion at Hoffman's Amp forum. He

proposed to build a 1960 Vox AC-15 for his studio. His idea was to develop a

layout for a single chassis, Marshall style amp. The unique vibrato circuit of

this amp has intrigued me for a long time. Soon I was caught up in Barry's idea

and began corroborating with him on this project. We swapped many ideas back and

forth, but soon realized we were headed two different directions. He wanted to

use two boards and keep a similar tube layout and control panel layout kinda

like the original, but put it all on a single chassis. I liked the idea of one

single board, tubes lined up across the back like a Marshall, and rearrange the

faceplate to fit the board layout. Barry soon became busy with his real life and

dropped off the forum. I don't know if he ever completed his project, but he's

to blame for my interest in the AC-15. I completed my layout but set it aside

and got busy with house remodeling and planning my retirement at the end of the

year. The AC-15 idea had faded.