|

February 18, 2013

The Warbler Revision 2, a

major overhaul

What

began as a simple mod to provide a LED front panel indicator for the vibrato LFO

turned into a major overhaul. What

began as a simple mod to provide a LED front panel indicator for the vibrato LFO

turned into a major overhaul.

Here's a summary of the changes:

- The MIX control is a carryover from Revision 1. It

allows blending the wet signal with the dry signal.

- The TONE control was added to compensate for the

slight loss of treble through the modulator circuit.

- The FOOTSWITCH jack allows easy on/off function for

the vibrato effect.

- The BAL pot allows you to match the "dry" signal

level to the "wet" signal level at the inputs to the mix pot. I used a scope

to match the signals but you can easily set the BAL pot by ear. Just turn

the MIX to max CW and note the sound level. Now turn the MIX pot max CCW and

adjust the BAL pot until the dry sound level is the same. Repeat until

you're happy, then lock the pot.

- The LED flashes at the rate of the vibrato

oscillator. Although the LED also increases the LFO output signal, the

Warbler doesn't benefit from the increased signal. So, it's purely a visual

thang.

- V1 and V2 have been replaced with 5751s. The 5751s

sound good and are not prone to microphonic problems that I was experiencing

with the batch of milspec 6189s (12AU7) I had been using. I think the 5751s

may sound a little more crisp than the 6189s.

- V3 circuitry has been totally removed. It was not

needed.

- Power supply nodes E and F have been eliminated.

- V1A gain has been reduced to about 3.5. The overall

gain (input to output) is about 2.5. The reduced gain results in quieter

operation but still provides a nice clean boost that can be set with the

LEVEL pot.

- DC voltages and AC signal voltages have been added to

the schematic.

All these changes are documented in the revision 2 pdf

available at the bottom of this page. I don't anticipate any further changes.

And here are the updated pics, plus a short tour around

the bench...

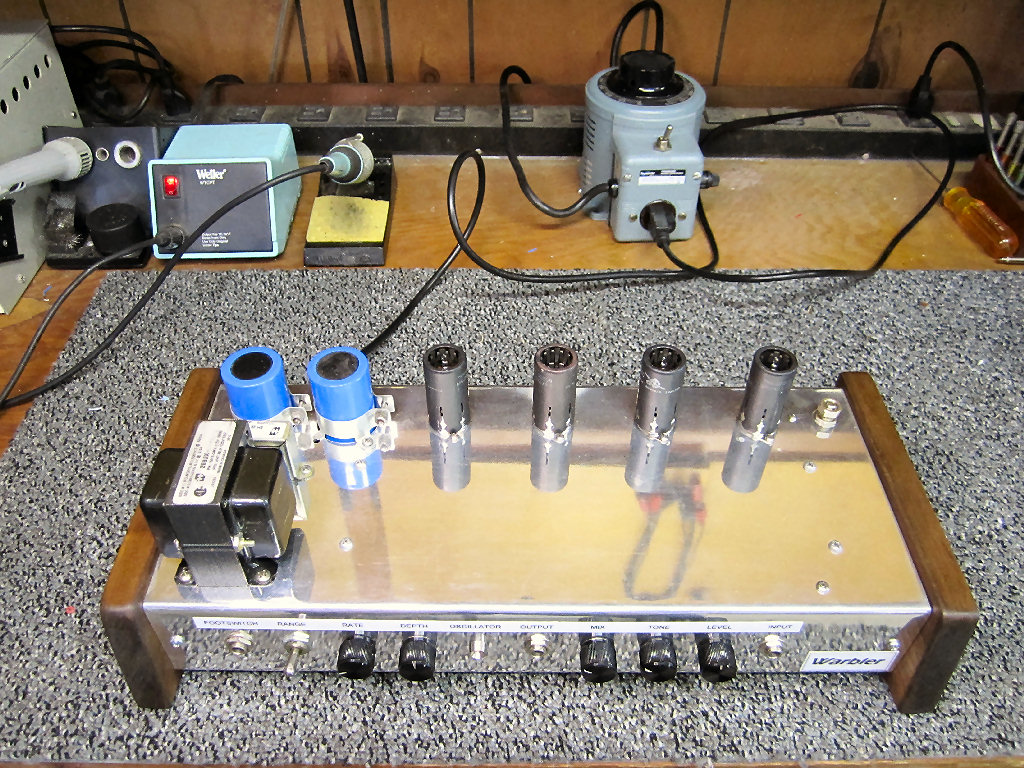

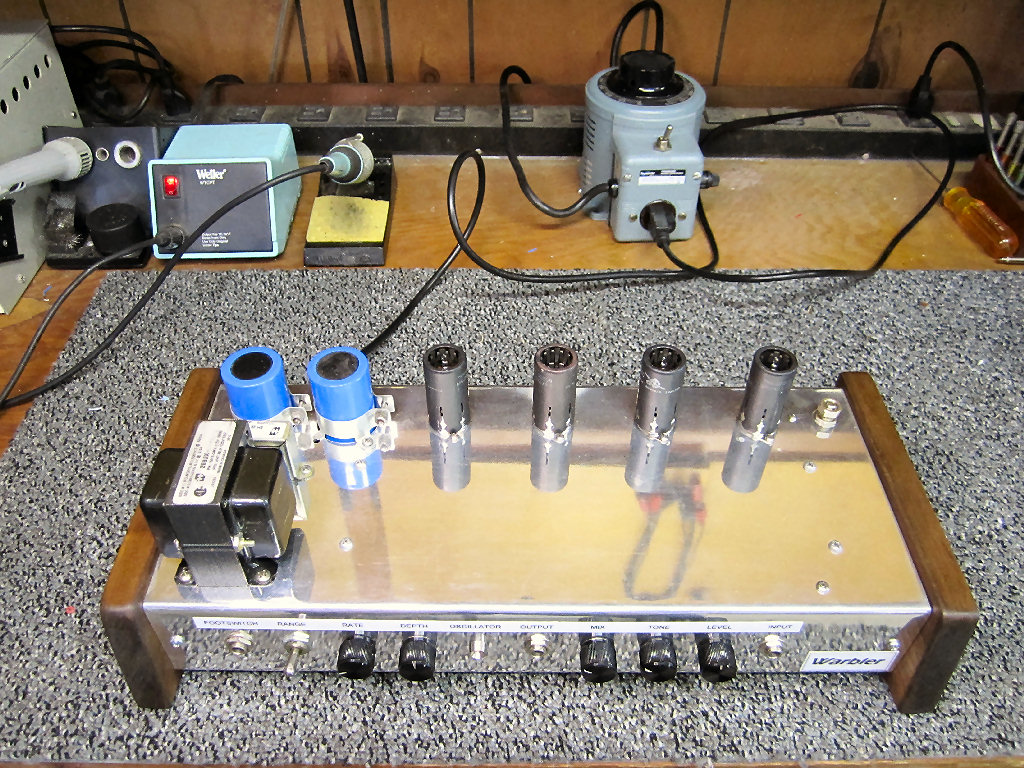

The control panel is busier now. Left to right... Footswitch

jack, range switch, rate, depth, oscillator LED indicator, output jack, mix,

tone, level, and input jack.

The balance pot was added just to the left of V1. It's

function is to match the "dry" signal level to the "wet" signal level at the

inputs to the mix pot.

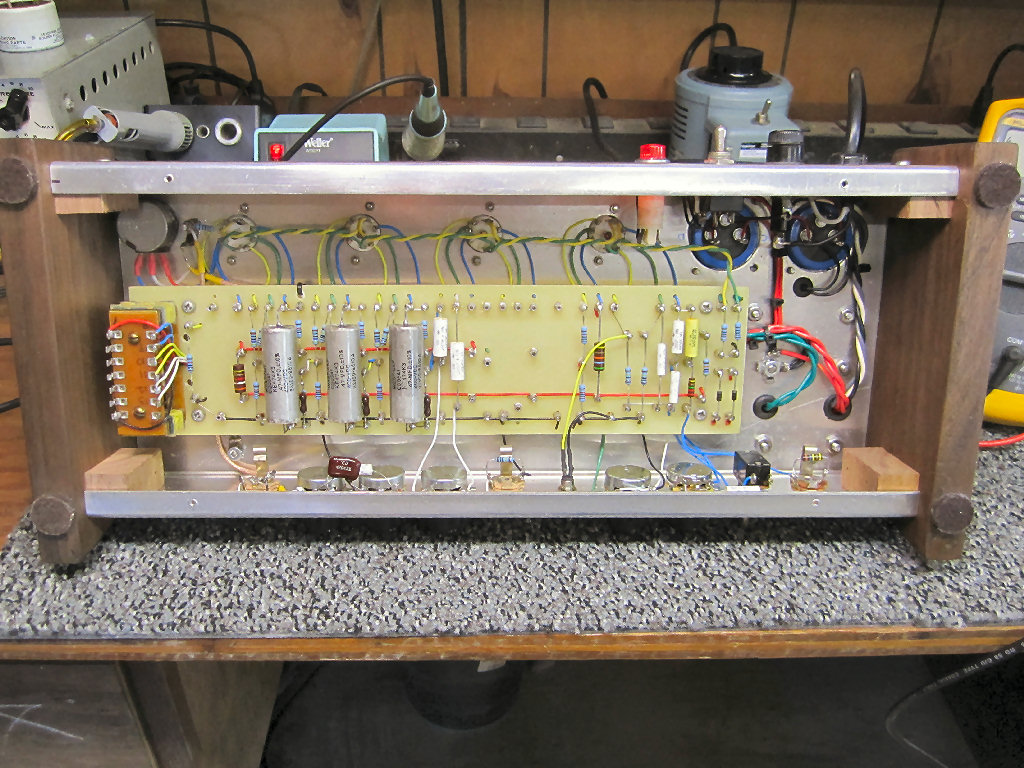

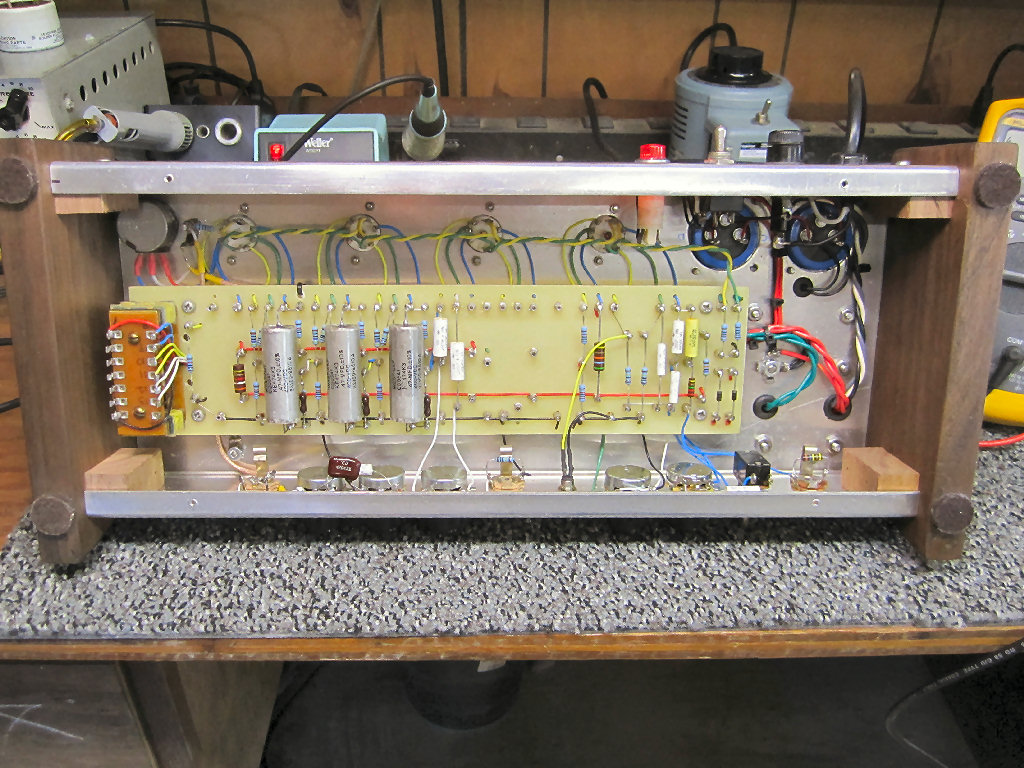

Not only has the control panel become busier, the board has

become less busy. A lot of components have been removed. Several values

have changed. And a few components have been added. The original 12.5" board

could now be shortened about 3".

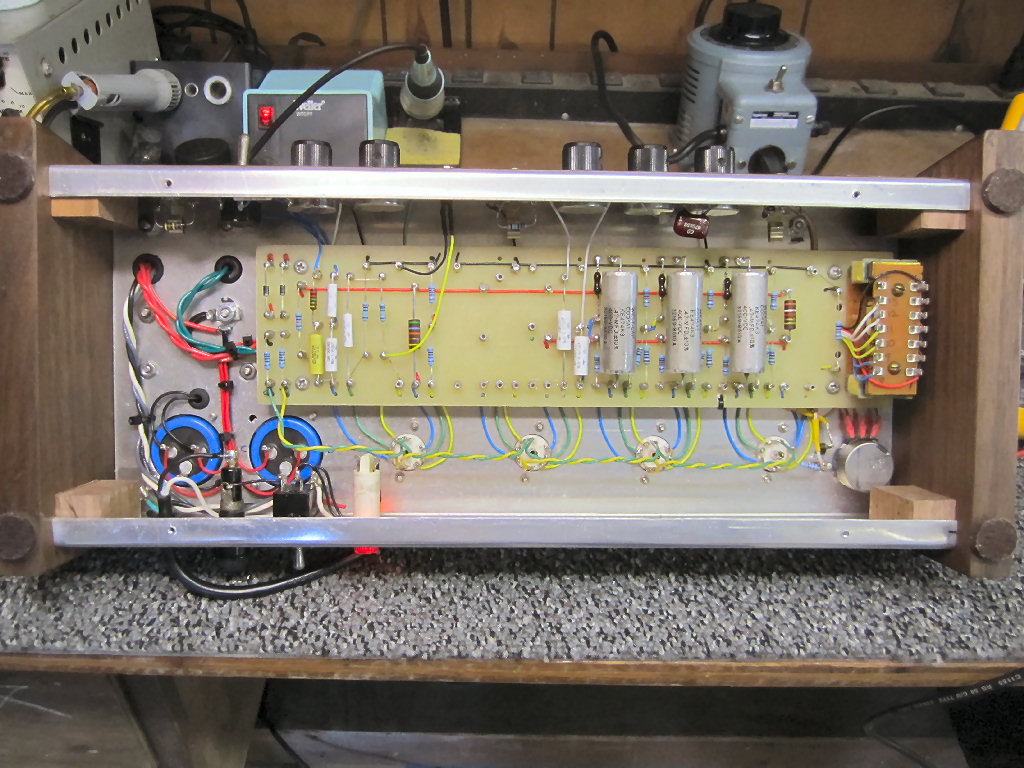

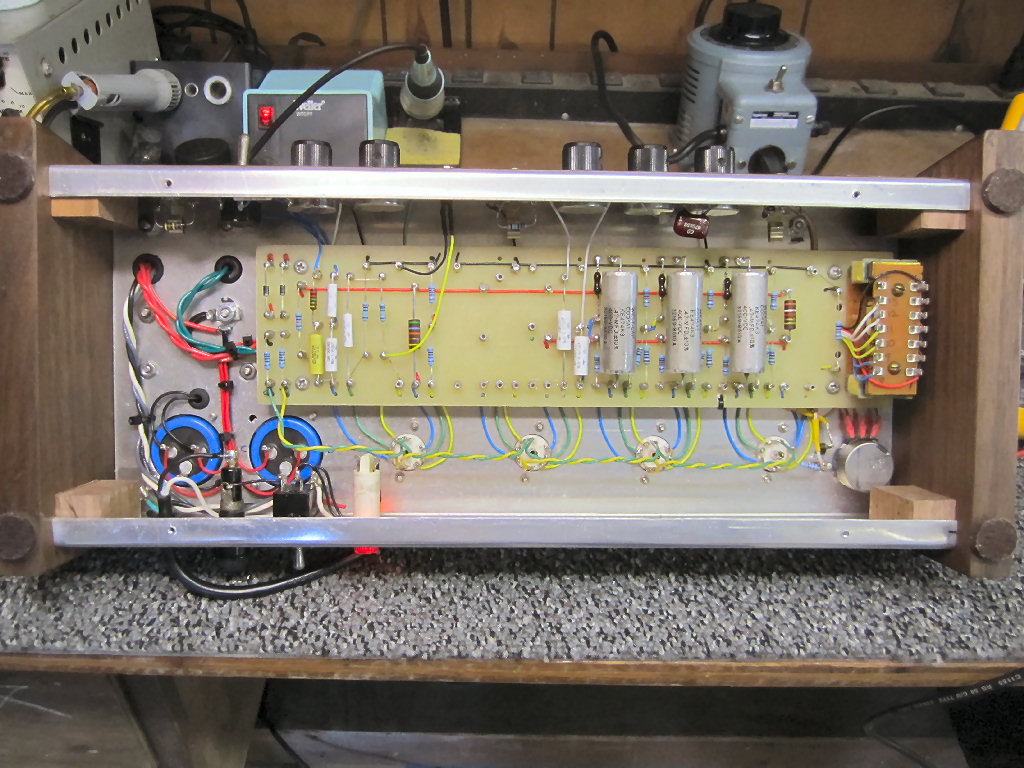

This view shows the chassis layout as seen in the board

layout drawing. I left the empty V3 socket in place rather than have to redo

the filament string. And who knows what revision 3 may bring!

And here's the work area. Not too big, not too small.

Just right for my hobby interests. The workbench is still somewhat cluttered.

Maybe now that I'm retired I'll have time to organize better.

If you let your eyes wander you'll see that this bench is

used for much more than just electronic projects. BTW, that Ampeg ain't

what it seems to be.

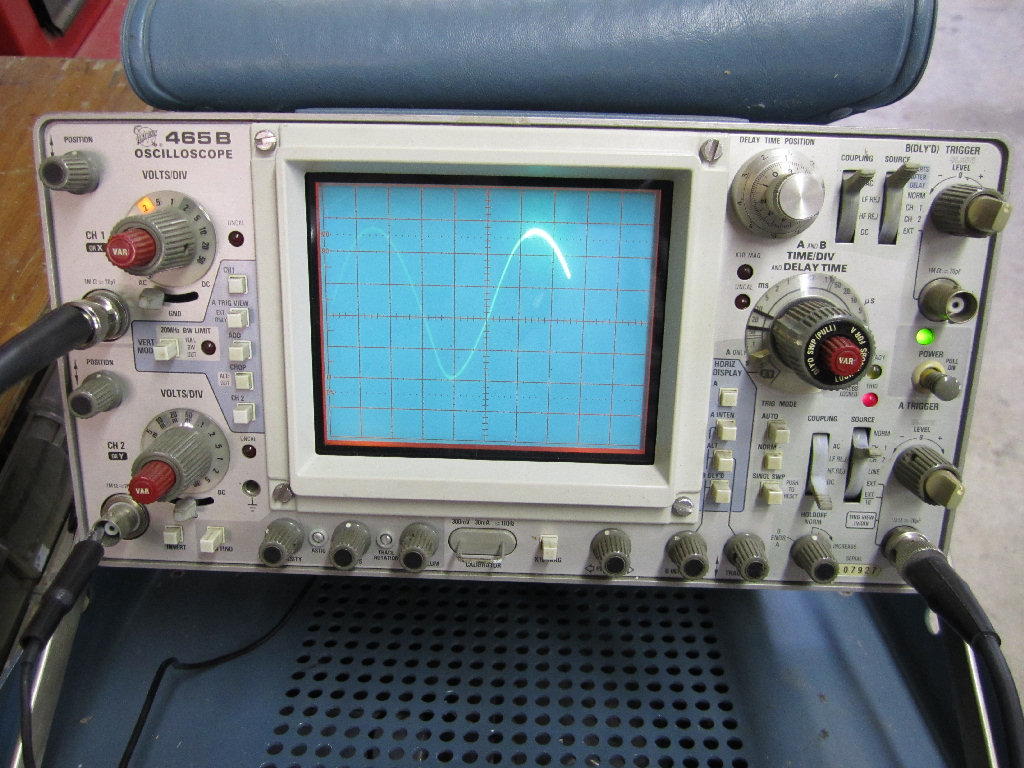

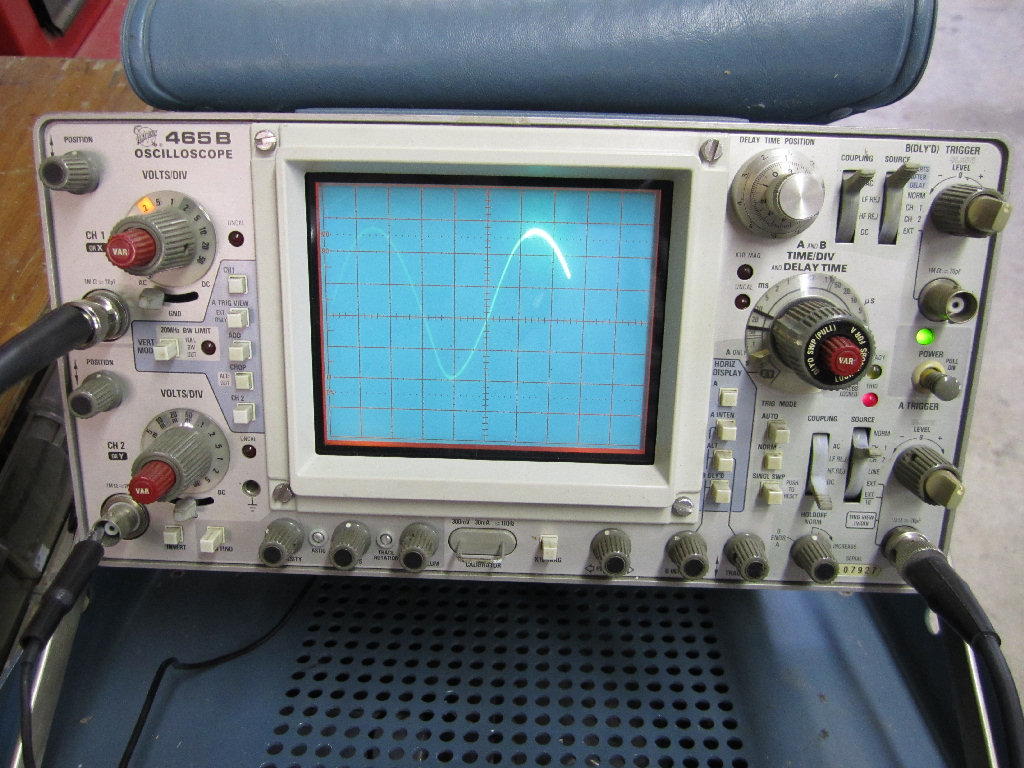

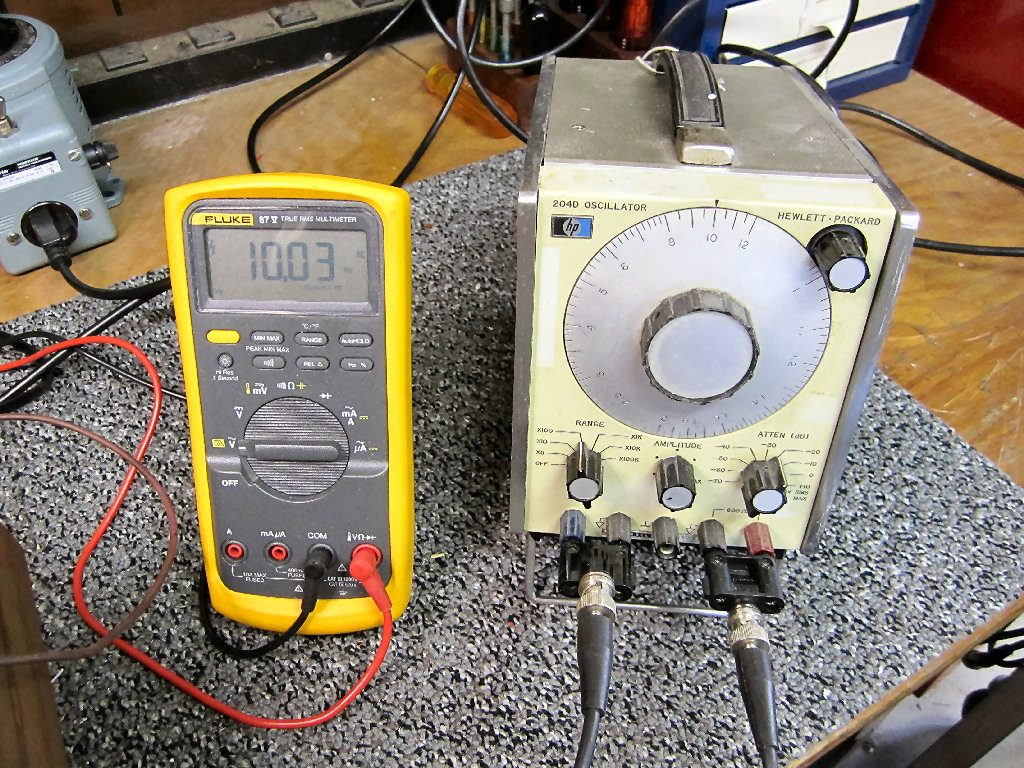

This is the test equipment that I used while building and

testing. These 3 pieces came from eBay. The scope cart was originally used for

the old Tektronix 545 tube scope.

The scope is displaying the LFO sine wave. Notice that it's

not perfectly symmetrical.

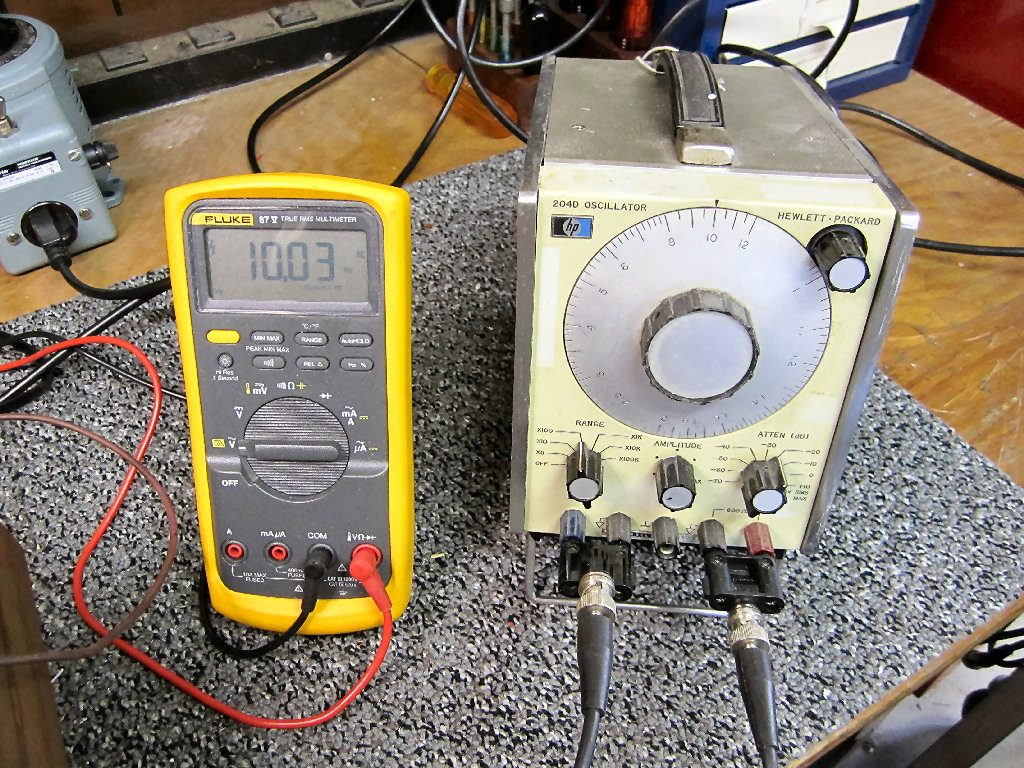

The Fluke 87 DMM is monitoring the vibrato LFO signal. It's

set to frequency mode and is displaying 10Hz. The HP 204D Oscillator is set to

provide a 200mV 1KHz sine wave signal to the Warbler input. It is also sending a

sync signal to the scope for external triggering. Triggering the scope

externally allows a stable display that is independent of the scope vertical

input. This setup allows the scope to display phase shifts as well as signal

levels as you step through the Warbler modulator circuits.

The Weller WTCPT soldering iron has been my choice since the

early '70s. And sitting just to the left is a Pace repair station. It has a

soldering iron, vacuum operated desoldering iron, thermal wire strippers, small

air compressor, and "Dremel-like" rotary tool. I mostly use it for desoldering

jobs.

Download the Revision 2 schematic and full size board layout in a single PDF

warbler_rev2.pdf

(181KB)

(Note. This revision contains

all the circuit changes mentioned above. This is the circuit I recommend building.)

Return to Index

|  What

began as a simple mod to provide a LED front panel indicator for the vibrato LFO

turned into a major overhaul.

What

began as a simple mod to provide a LED front panel indicator for the vibrato LFO

turned into a major overhaul.