|

October 24, 2023

Wood Turning... Those damn

bowls!

After the lamp project turned out so well I decided to do some bowl turning.

I have several various size blanks that have just been collecting dust since

the '80s. So I picked a small one to practice on and set it on the ShopSmith

to evaluate and develop a simple plan that would be easy for a rusty turner

to test his skills.

The first bowl!

I had started turning this mahogany blank back in the '80s but put it on a

shelf. 35 years later I decided to see if I still had any turning skills.

This 7" bowl was the perfect practice project.

It's amazing just how much sawdust a small bowl can hold! Just look at that

mess.

...Finishing up the bottom of the bowl is usually the last step.

The perfect size for a small "catch all" bowl.

Turned out pretty good. Still need to work on some techniques and then move

on to a little bigger project.

The

second bowl!

This 9" bowl was

originally intended to be something else and I can't remember what, but

definitely not a bowl. It presented some special challenges to convert to a

bowl. The rim is a bit thick just in case it gets fitted with a lid later.

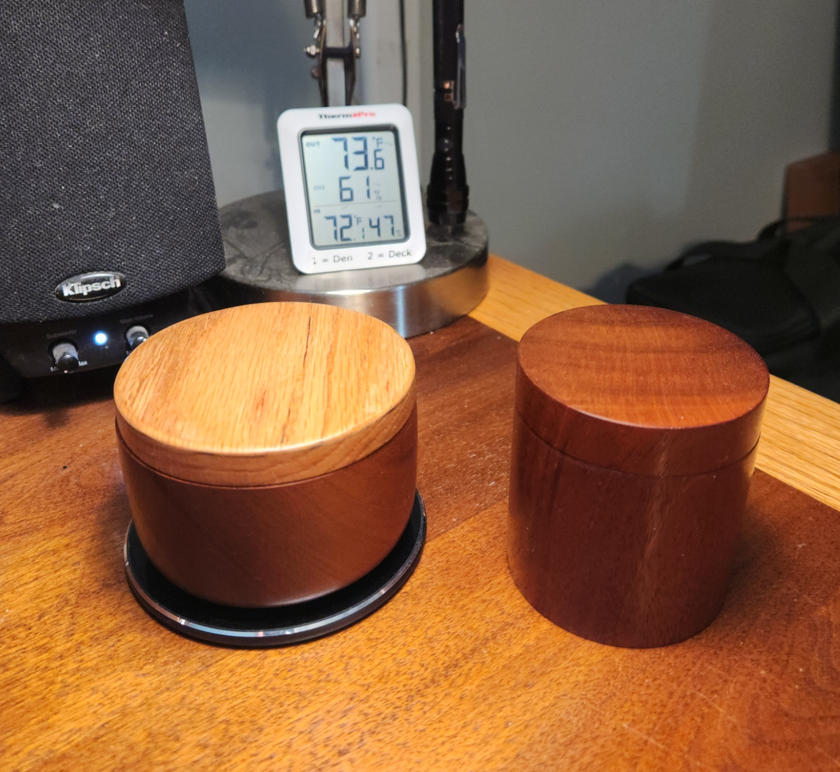

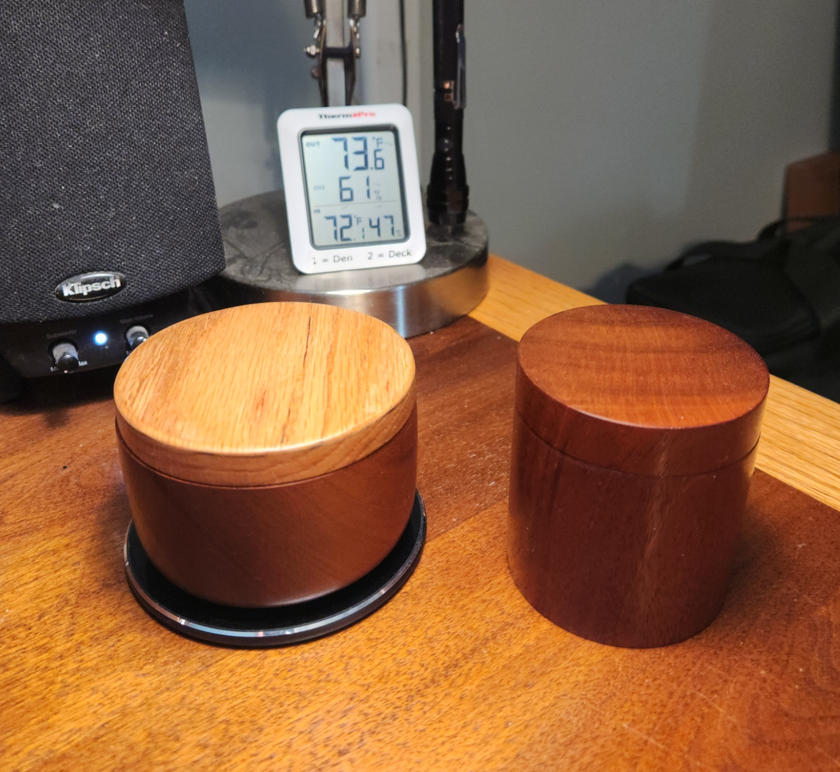

The stash boxes

These small boxes are

great for storing all kinds of small goodies.

The Shop Is Changing!

No more rosin fumes!

The shop smells like aromatic red cedar today. Beginning to look more like

a woodshop too.

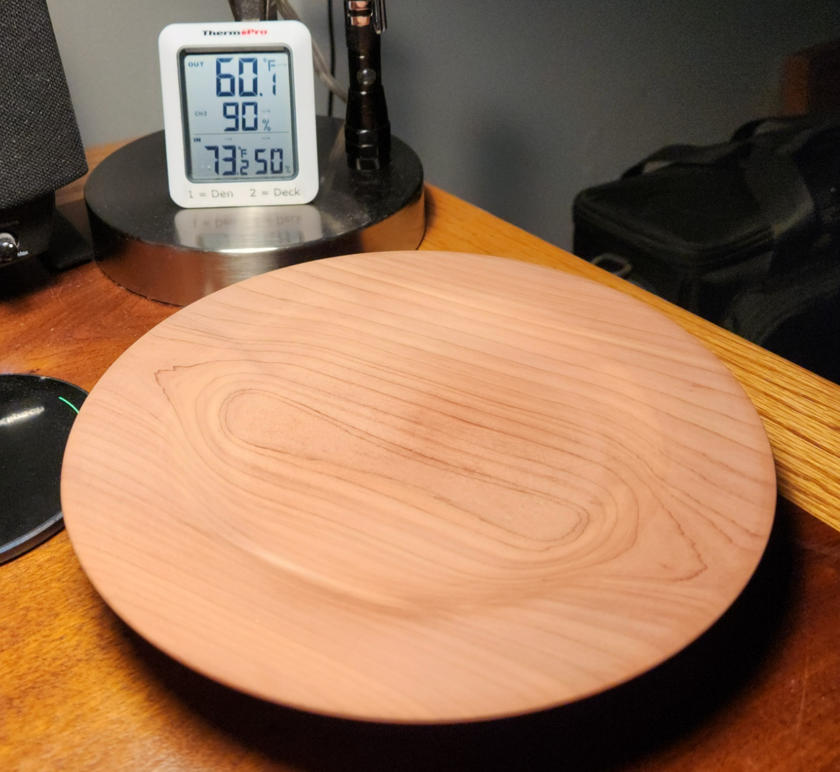

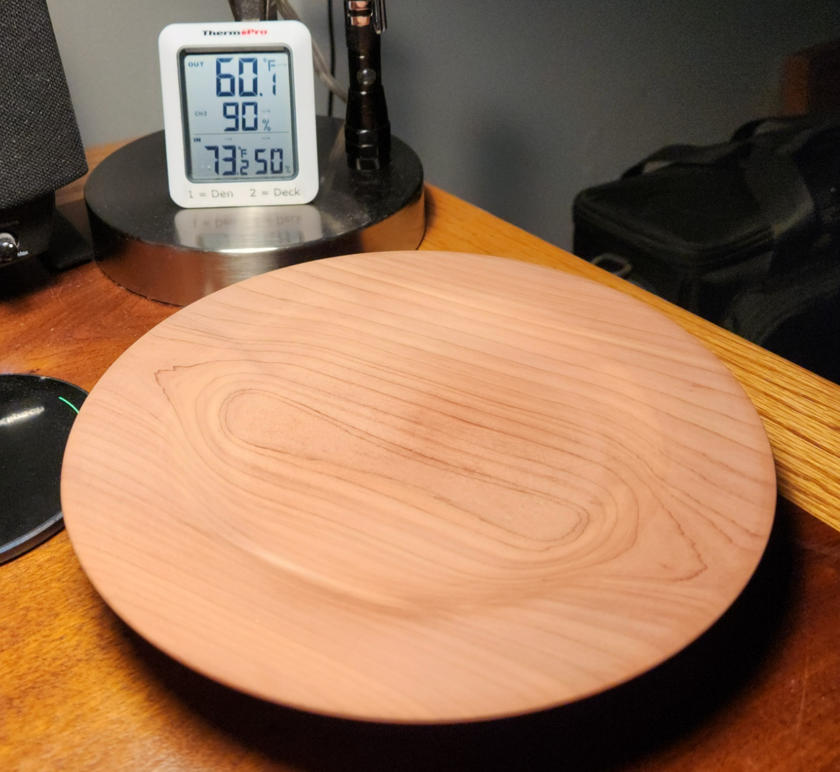

Eastern Red Cedar bowl

Clear Cedar turns like

butter but those knots are hard as rocks. I need a steady hand and light

cuts. And sharp tools!

Yay!!! I got a serious

grinding station for my birthday.

I'm not gonna put a

finish on it for now. I want to keep that cedar smell as long as I can. I

may eventually clear coat the outside.

The inside and outside

are as smooth as silk

Today I made a 8.5"

cedar plate.

Nice companion for the cedar bowl.

Merry Christmas Amy.

Other lathe projects

Mahogany mirror

and oak hall tree. Yeah I know. They're not bowls. but just wanted to say I

was not totally fixated on bowls. I also did a lot of spindle

turning back in the '80s. I've always enjoyed projects that incorporated a

lot of different woodworking techniques.

The scrap

bowl. We'll see...

Today while scratching around in a drawer looking for an air compressor

fitting, I found these glued up extras and cut-off pieces from my '80s lamp

project. I put then on the work table and started shuffling them around.

Then I came up with a plan for a small bowl. The idea is to glue four

maple/paduck cutoffs

to a mahogany square and then sandwich the glued up feature ring between two

more pieces of mahogany. The idea sounds good. We'll see if it really works

out...

One of

the feature ring pieces slipped a bit during glue up. Luckily it was glued

to end grain so I was able to split it off easily and reattach. Looks better

now.

Ready

to build a sandwich!

All glued up. Tomorrow

should be fun.

I used a faceplate to mount on the lathe and turned true. Gonna study it for a while to see if

I get some ideas.

It's gonna be a cookie cannister. We got enough damn bowls! Just put a lid

on it, fill it with Christmas sugar cookies, and put it under the tree for

someone special. Time to reverse chuck it and hollow the inside.

Faceplate removed and

bowl reversed and mounted on chuck. Inside turning and sanding done. Ready

for several coats of MinWax wipe on poly.

Waiting for paint to

dry is pretty boring so I mounted a small blank on my wood screw and turned

a knob for the lid.

The final piece! The finishing process is gonna take a while because of the

recent high humidity. Each coat needs 24 hours to cure and I want at least

four coats, maybe more. I'll be back when it's done.

Reverse mounted (for

the final time) on my

Cole jaws to remove the tenon. This completes the turning process. Final

assembly coming up.

All done! Glad I kept those lamp scraps all these years.

Just needs some Danish

butter cookies and hide it 'til Christmas. This is for my wife Carol.

Sharp Dressed ShopSmith

I've been working on the ShopSmith for the past two weeks. This time I did a

complete disassembly. Then I thoroughly cleaned it and removed all the rust

and aluminum crud. Then two coats of rustoleum, a new set of casters that

actually roll smoothly, and a complete set of shiny tubes from eBay.

10/11/2023... Back in

action after 35 years.

12/08/2023...Set up in disc sanding mode.

Seems a shame to take'em

to the curb. They served well since '79. Maybe I'll just put them in a

corner.

Another Christmas Cedar

Bowl

For the bowl blank I

glued up two pieces of 2" x 9" x 9" eastern red cedar. The lid will be

turned from a 1" x 9" x 9" stock. And the knob will be turned from cedar

scraps.

All

done...

... and

ready to wrap. This is for my daughter Megan.

12" Mahogany

platter

Just in time for

Christmas goodies!

6" Mahogany

goblet

Fail? Maybe not...

Saved! I sanded the bottom of the top part flat and turned the base into a

lid to create this small box. I know what went wrong with the goblet and

will try again.

Finally got the time to try take 2 on the goblet. Everything went well until

the final cut. I was so happy that everything was going as planned. But, I

got a bit overconfident and a little heavy handed, and while cutting the

base a 1/4" chunk blew off! Damn! I knew this wood was brittle and required

a light touch! Spent another 5 minutes salvaging that. Now the base

has a smaller diameter and slightly different shape than I had planned.

Nevertheless, I'll keep it.

Band of Angels gets new set of wings

I made this band of

Angels sometime in the mid '80s. It was a Christmas gift for Carol. Every

year since then they were brought out of storage as part of our Christmas

decorations. Through the years they all lost at least one wing maybe due to

repeated storage, but most likely at the hands of curious toddlers.

Yesterday I gave them all a new set of wings. I think they actually sound

better now!

Pedestal Bowl

I found a piece of 4x8 crotch mahogany that was left over from a

different lamp project back in the '80s. I cut a 4x8x8 piece and decided

to try my hand at a pedestal bowl.

That crazy crotch

grain is beautiful but was quite a challenge for my rusty turning chops.

Still turned out good IMO.

A fancy cedar bowl with lid

I started this 6" bowl in the '80s but it has a split in it so I set it

aside. Later I would keep cedar sawdust in it for filling cracks. Then

it just got lost in the junk in my shop. Yesterday I came across it and

decided to put it back on the lathe. I put enough CA glue in the split

to hold it together then turned the outside to a new shape. I also

turned a fancy lid. I used a friction polish made with equal

parts shellac, boiled linseed oil, and denatured alcohol. Super easy to

apply while still on the lathe. Wipe on, wait a minute, turn the lathe

on and polish with a paper towel. The friction from the turning lathe

and firm hand pressure makes it work. You are doing it right when your

fingers get warm! Three coats only took 15 minutes. It's not as durable

as wipe-on poly but does not require several days to finish either. I'm

pleased.

Return to Index

|